- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

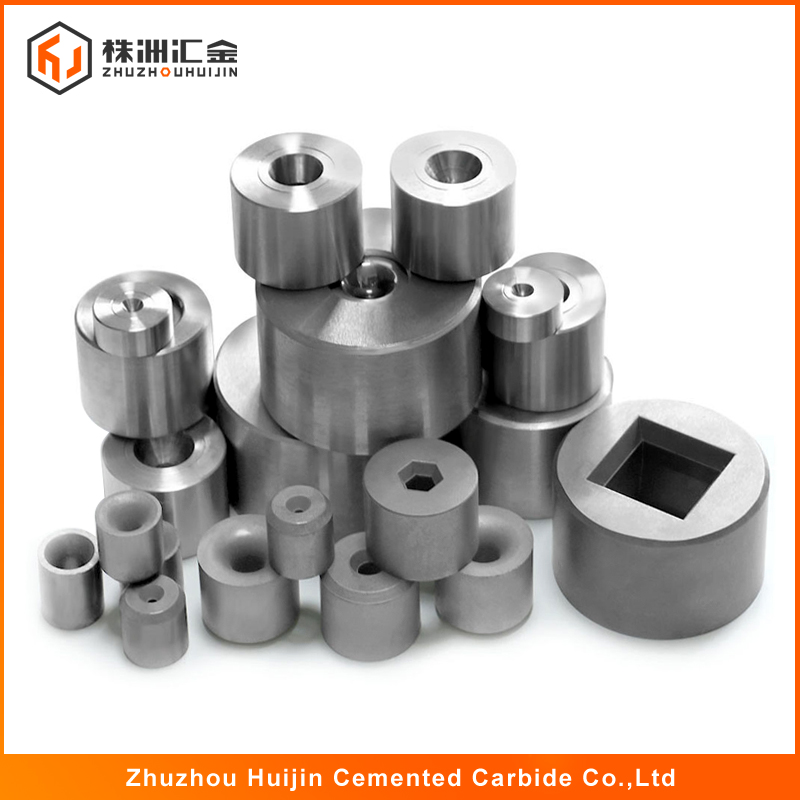

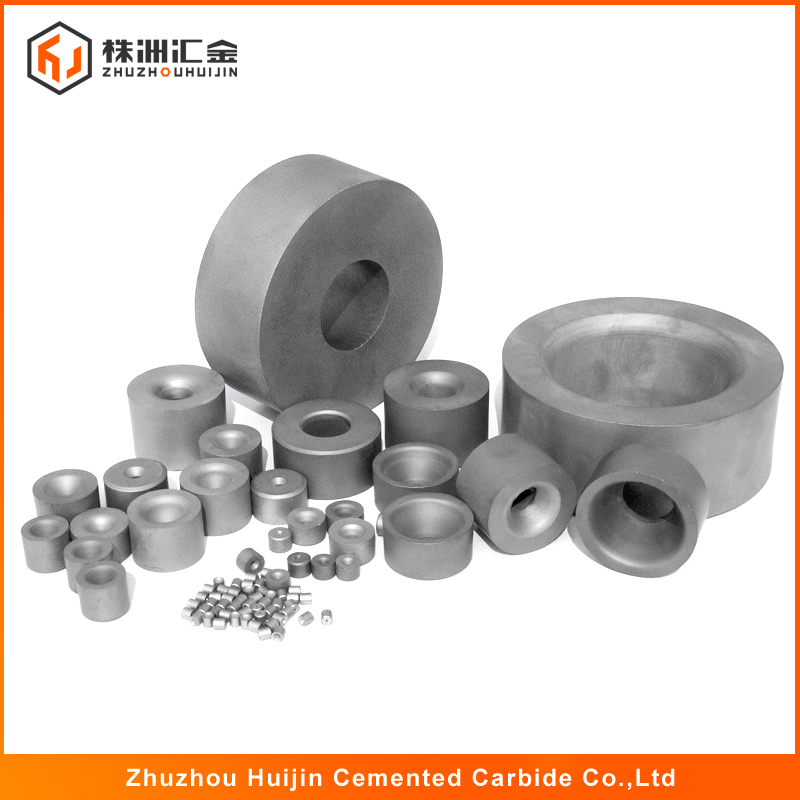

Tungsten Carbide Wire Drawing Dies

carbide Wire Drawing Die Tungsten Carbide Punching Mold

wire moulding tungsten carbide wire drawing dies

customized non standard die

Tungsten Carbide Punching Mold

Tungsten carbide drawing dies are a wise economical choice for steel wire and other large-size wire

drawing applications that make cost savings a priority over die wear resistance and wire surface finish.

Cemented carbide drawing dies are used in wire drawing industries for drawing of different materials

like mild steel (M.S), high carbon (H.C), stainless steel (S.S), brass, aluminum and more. All major

wire producers use tungsten carbide drawing dies.

Tungsten carbide drawing dies from Zhuzhou Huijin Cemented Carbide Co. Ltd, are composed by

micro crystalline rare refractory metal carbide and high-purity cobalt powder for auxiliary metal or other

metal powder as the binder. As a result of special production methods, and use of international

advanced low pressure sintering furnace, the alloy is not only to maintain the original valued properties

of tungsten carbide, and its performance increased by 1/4 than ordinary drawing die. At the same

time, due to cobalt or other metal for cement, it becomes also tough.

product feature

1. Good wear resistance

Tungsten carbide possesses high wear resistance, which could guarantee long-term work of drawing

die within any drawn amount and ensure the size and precision of products.

2. Excellent polishing

Carbide has a good polishing, which can be processed like mirror, thus ensuring high-quality of metal surface.

3. Small adhesion

In the drawing process, the drawing die keep little adhesion with metal processed, thereby enhancing

the durability of drawing die, and make processing material to acquire high-quality gloss finish for surface.

4. Small friction coefficient

In the drawing process, small frictional resistance can greatly reduce the power loss, thus enhancing efficiency.

5. High coefficient of thermal conductivity

In the drawing process, heat can be conducted away very well.

6. Good corrosion resistance

The property is in the wet lubricated stretch, especially in the acidic lubricated stretch, to become more superior.

product show

Tungsten Carbide Drawing Molding Die apply to Wire and cable, aluminum wire, ladle steel wire, ladle

copper wire, steel wire rope,high carbon steel wire, stainless steel wire, nickel wire, chrome wire, copper

clad steel wire, cutting wire, steel cord, welding wire, copper pipe , stainless steel tube, etc.

Necessary information required for accurate quotation :

Specification ( like OD*ID*Length size,shape,angle etc.)

Surface condition: sintered blank or fine grinding

Tolerance on dimension ( if you have)

If you have detail drawing contain all above information ,you can send drawing to us Tungsten carbide grade, or chemical composition.

If you are not quite clear about which tungsten carbide grade is suitable, please provide us the applications,we will suggest suitable grade base on your

公司拥有从粉末原料制备、模具制作、压制、压力烧结、磨削、涂层及涂层后处理的完整叶片制造工艺装备生产线。专注于硬质合金数控刀片的母材、沟槽结构、精密成形及表面涂层的研究与创新,不断提高硬质合金数控刀片的加工效率、使用寿命等切削性能。经过十余年的科研创新,公司掌握了多项自主核心技术,具备自主研发设计能力,可为每位客户提供定制化生产。