- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

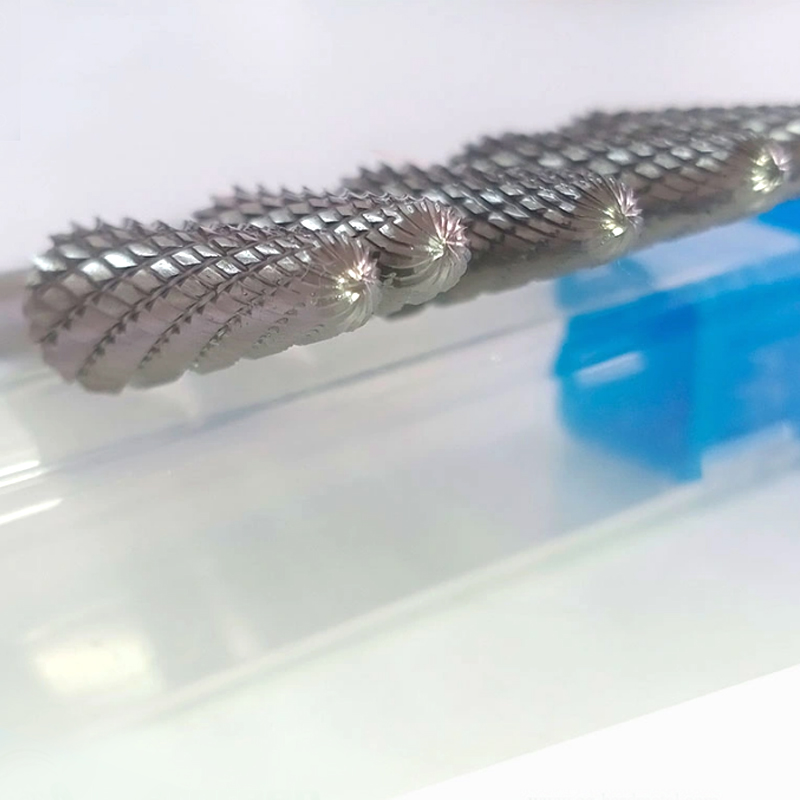

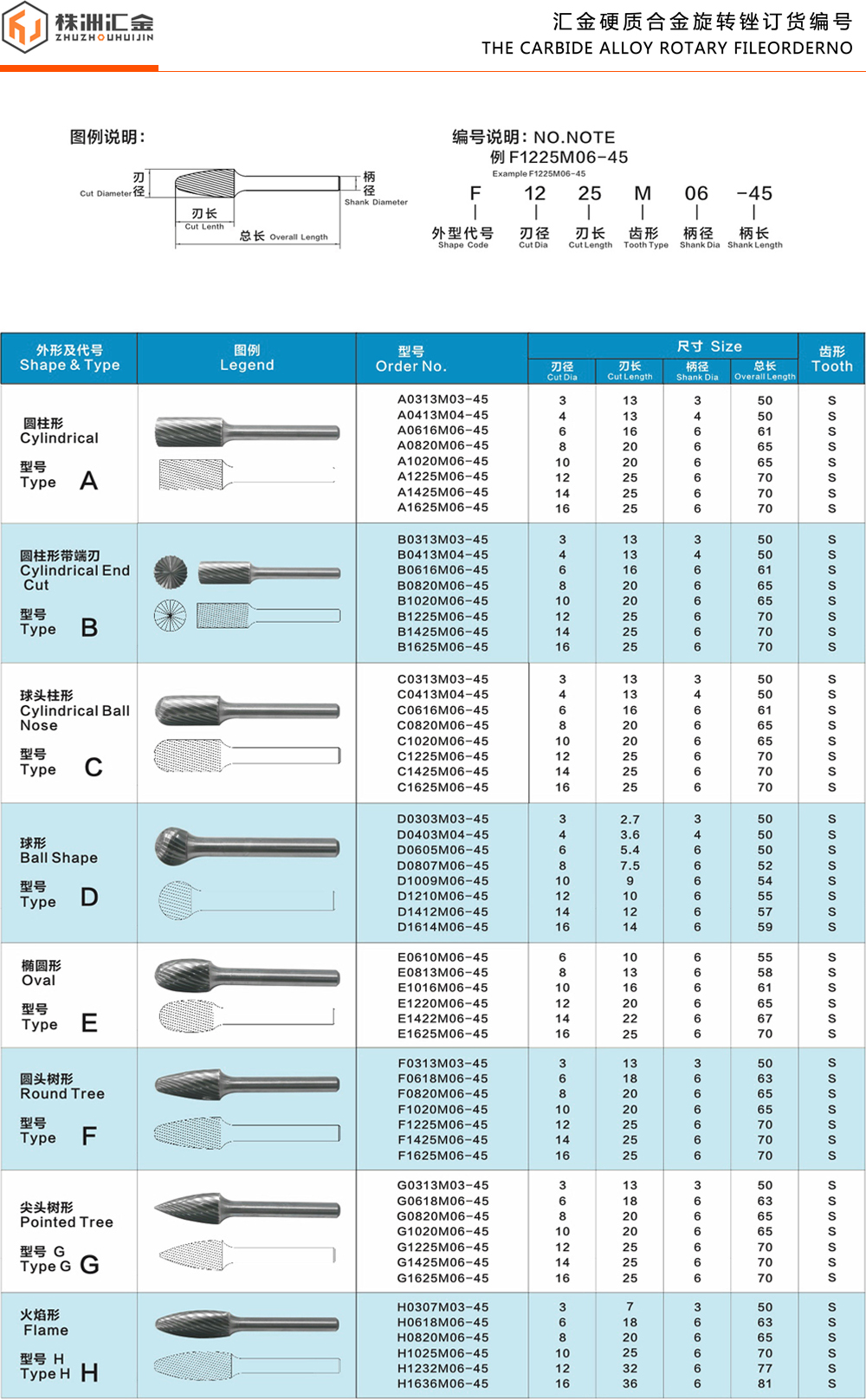

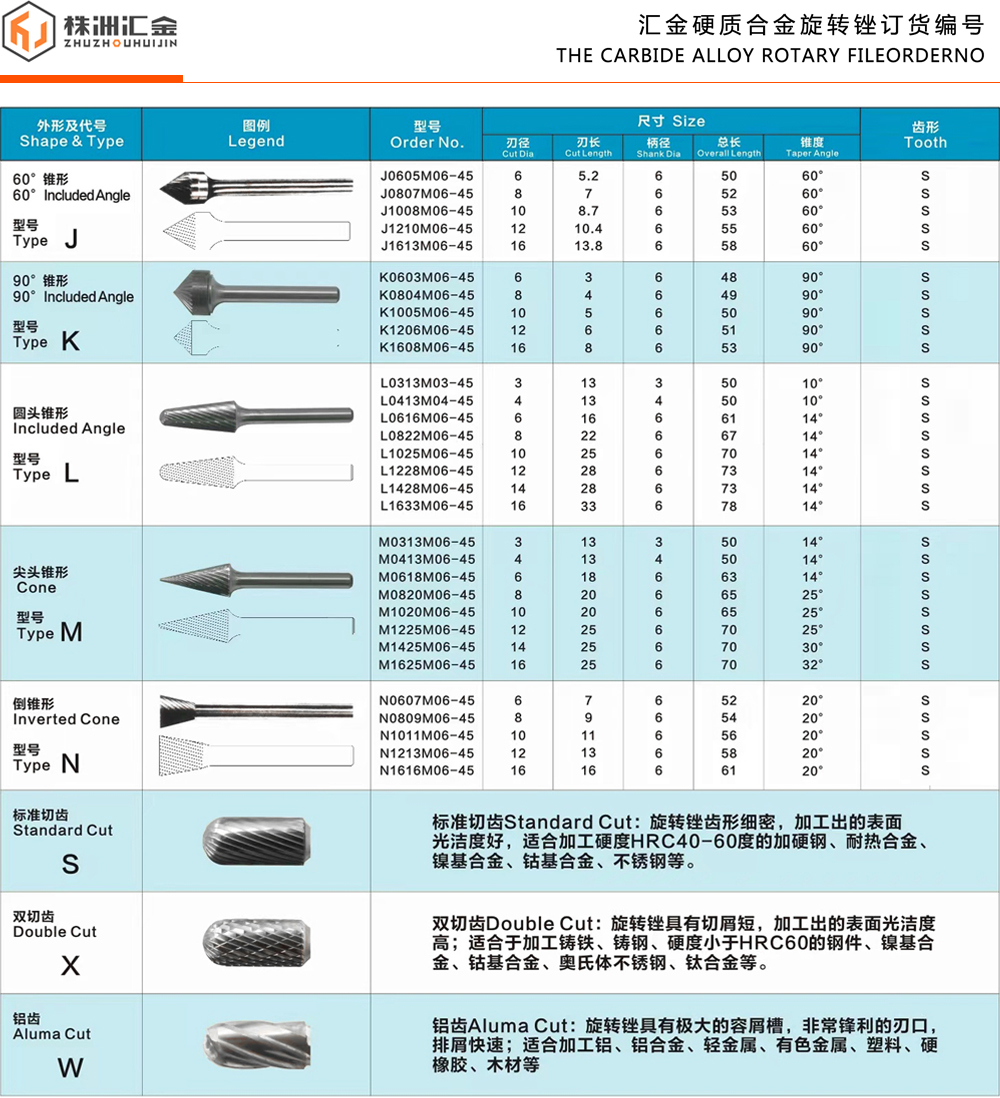

Metalworking Rotary Files Tungsten Carbide Steel Rotary Burr Bit Set

Polished Single Cut Double Cut Tungsten Carbide Burrs

Polished Tools Carbide Tungsten Rotary Files burrs

Custom Different Types Tungsten Carbide Rotary Burrs 10Pcs/Set

Carbide Rotary File Rotary Burrs Milling Cutter Tungsten Steel Grinding Head

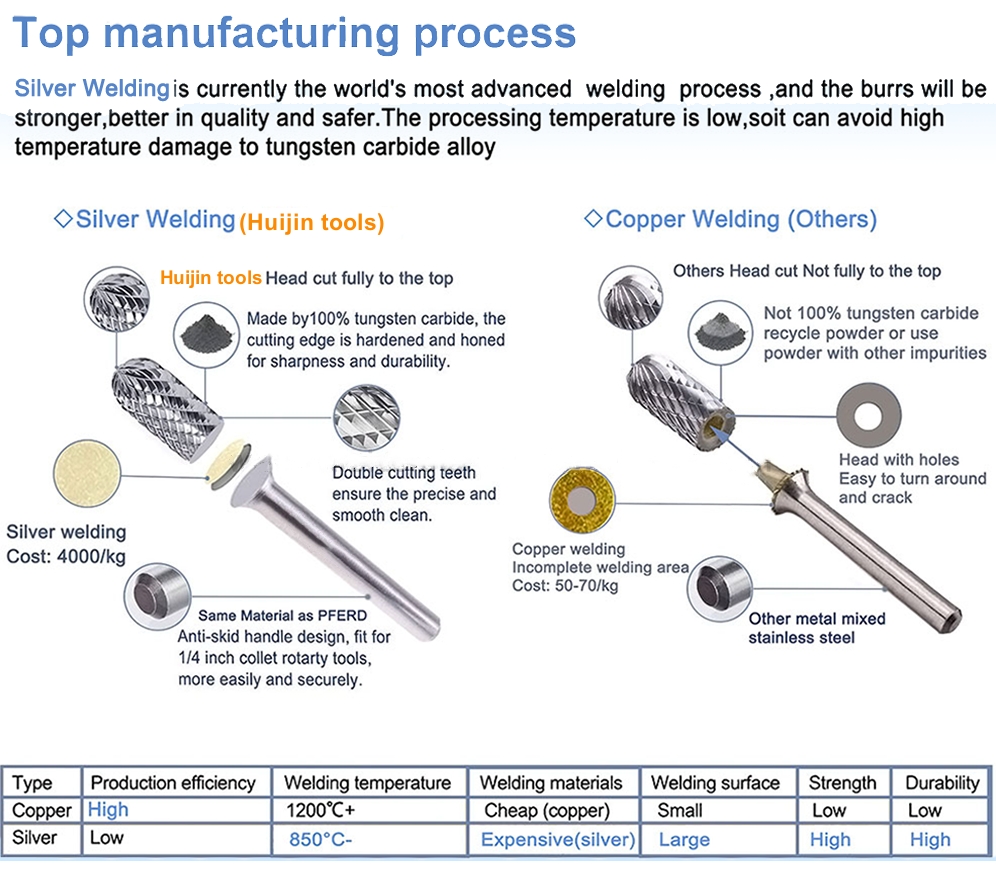

welding: silver welding

Carbide Rotary Burrs are perfect for fine detail work,widely used for metalwork, woodworking, model engineering

, wood carving, jewelry making,welding, chamfering, casting, deburring, grinding,ect; Our high-performance

carbide rotary burrs provide maximum cutting edge stability with a simultaneous high tenacity of the cutting edge, and

we can also provide custom solutions according your applications.

Material: 100% of raw materials.

Tolerance: strict tolerance extent control, which can reach +/-0.01mm;

Grades: various for choice: YG6, YG8, YG8C, YG11C,YG15C and so on.

Types: standard, conical, parabolic,ballistic

Physical performance: high hardness and impact toughness, very good mechanical & chemical stability.

Cemented carbide rotary file is widely used in machinery, automobile, ship, chemical industry, craft carving and other

industrial sectors, with remarkable effect. Its main uses are:

-- Fine machining various metal mold cavities.-- All kinds of metal, non-metal carving, and carving of craft gifts.

--Clean the flash, burr and weld of castings, forgings and weldments

--Chamfering, rounding and groove processing of various mechanical parts, cleaning of pipes, and finishing of

inner hole surfaces of mechanical parts

-- Polishing of impeller runner.

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

-Express companies: DHL, FedEx, TNT, UPS, etc.

-Airlines.

-Ocean shipping

A. Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product)

Şirket, toz hammadde hazırlama, kalıp yapımı, presleme, basınçlı sinterleme, taşlama, kaplama ve kaplama sonrası işlemlerden oluşan eksiksiz bir bıçak üretim proses ekipmanı üretim hattına sahiptir. Karbür NC uçların temel malzemesi, oluk yapısı, hassas şekillendirme ve yüzey kaplaması konularındaki araştırma ve yeniliklere odaklanır ve karbür NC uçların işleme verimliliğini, servis ömrünü ve diğer kesme özelliklerini sürekli olarak geliştirir. On yılı aşkın bilimsel araştırma ve inovasyonun ardından şirket, bir dizi bağımsız temel teknolojide uzmanlaştı, bağımsız Ar-Ge ve tasarım yeteneklerine sahip ve her müşteri için özelleştirilmiş üretim sağlayabiliyor.