- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

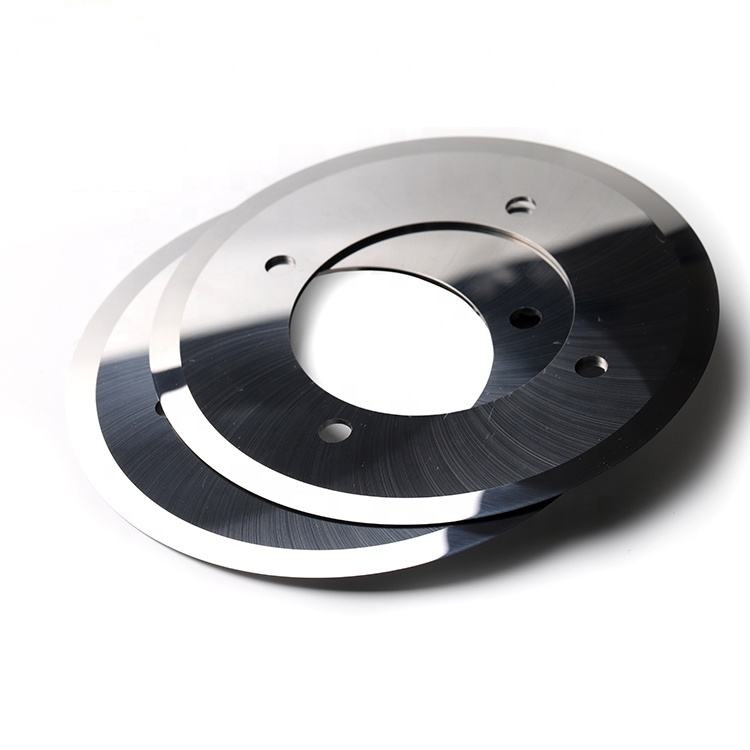

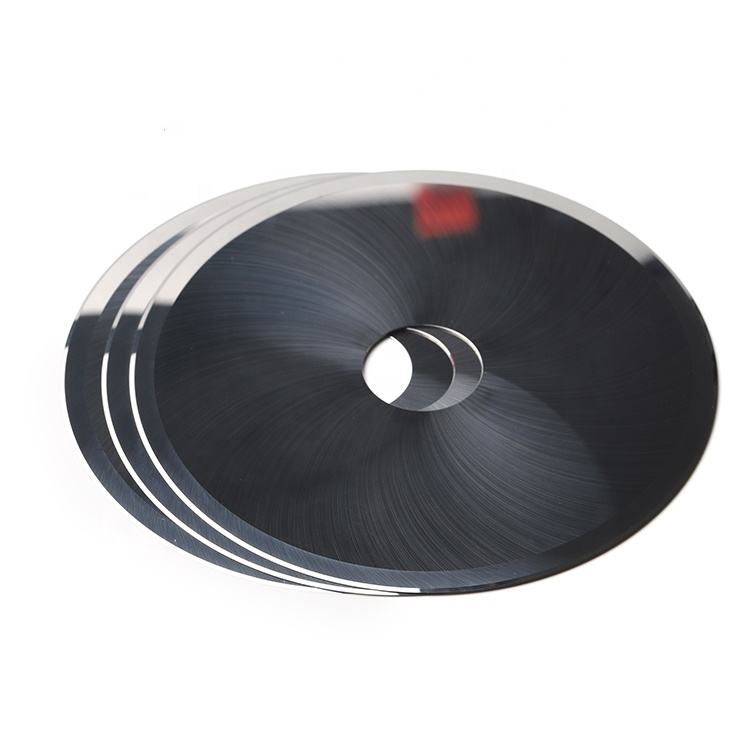

Tungsten Carbide Corrugated Cardboard cutter

Corrugated Cardboard cutter

Service : OEM and ODM

Application: corrugated slitter scorer machine

Surface: grinding and polishing to mirror

Working life: 7-9 millions meters

Tungsten Carbide Corrugated Cardboard cutter

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

In addition,we can provide the grinding wheel for the blade,slotting blade and others blade used for carton ,tobacco machinery.

material grade :

| Grade | Grain size (um) | Cobalt content (100%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm2) |

| YG6X | 0.8-1.2 | 6 | 14.8 | 91 | 2000 |

| YG10X | 0.8-1.2 | 10 | 14.42 | 91.8 | 4000 |

| YG12X | 0.8-1.2 | 12 | 14.5 | 89.5 | 2600 |

| Material grade | Tungsten Carbide YG10X, YG13X, OEM | |||

| Thickness | 0.2-6mm or customized | |||

| Flatness | 0.003mm | |||

| Type of edge | single edge, double edge | |||

| HRA | 85-93 | |||

| Straightness | <0.1 | |||

| Surface roughness | Ra0.2 | |||

| Laser engraving | Done as requirement | |||

| Package | 4 pcs/set,Simple packing/Plastic box packing/Blister packing | |||

| Main Size | OD(mm) | ID(mm) | Thickness(mm) | Cutting Edge |

| 300 | 112 | 1.4 | double | |

| 280 | 168 | 1.4 | double | |

| 265 | 112 | 1.3 | double | |

| 260 | 168 | 1.4 | double | |

| 260 | 140 | 1.4 | double | |

| 240 | 132 | 1.2 | double | |

| 230 | 110 | 1.3 | double | |

| 140 | 46 | 0.5 | single | |

| 100 | 16 | 0.3 | single | |

| 85 | 16 | 0.25 | single | |

| 60 | 19 | 0.27 | single | |

| Size | Can be customized according to customer requirements | |||

| Advantages | 1, High quality raw materials. | |||

| 2. Durable & Long service life. | ||||

| 3. High precision. | ||||

| 4. Nice and solid packaging. | ||||

| 5. Excellent weather resistance and waterproof. | ||||

| Application | For paperboard/paper/cardboard/carton/Tobacco machine to cut. | |||

Şirket, toz hammadde hazırlama, kalıp yapımı, presleme, basınçlı sinterleme, taşlama, kaplama ve kaplama sonrası işlemlerden oluşan eksiksiz bir bıçak üretim proses ekipmanı üretim hattına sahiptir. Karbür NC uçların temel malzemesi, oluk yapısı, hassas şekillendirme ve yüzey kaplaması konularındaki araştırma ve yeniliklere odaklanır ve karbür NC uçların işleme verimliliğini, servis ömrünü ve diğer kesme özelliklerini sürekli olarak geliştirir. On yılı aşkın bilimsel araştırma ve inovasyonun ardından şirket, bir dizi bağımsız temel teknolojide uzmanlaştı, bağımsız Ar-Ge ve tasarım yeteneklerine sahip ve her müşteri için özelleştirilmiş üretim sağlayabiliyor.