- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

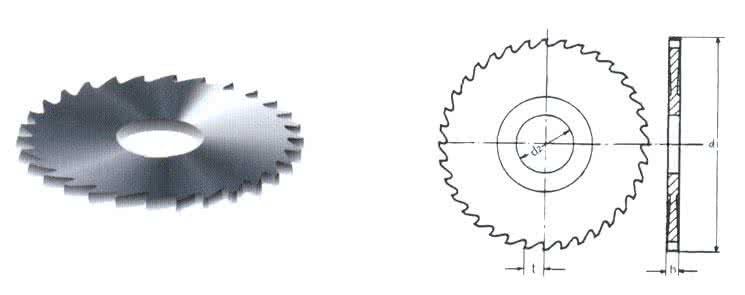

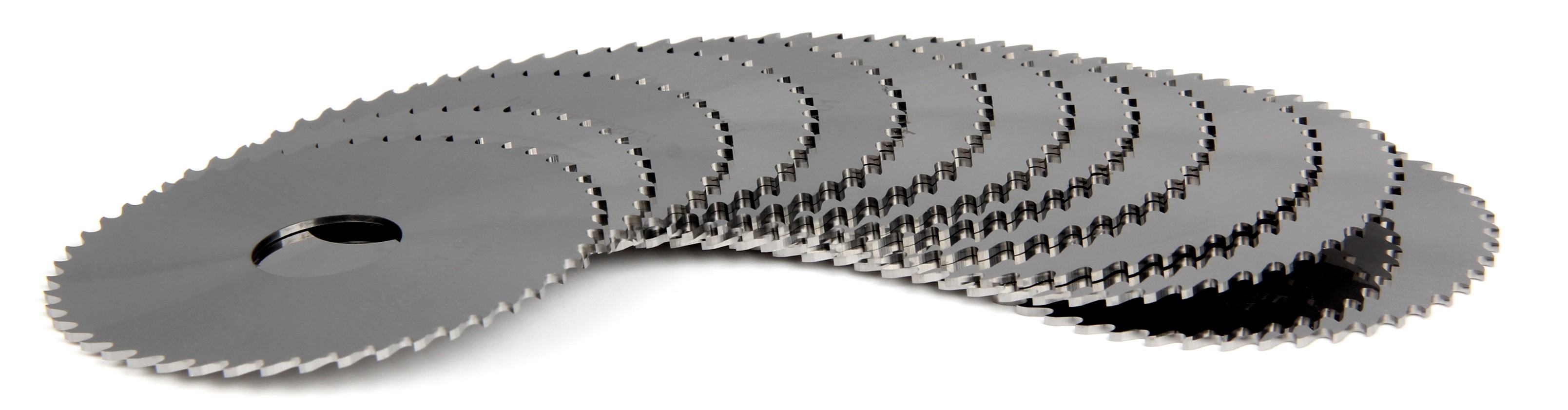

Tungsten carbide round cutting saw blades

Carbide saw blade cutter

Sizes : 75*25.4*T1.0-72T

Suitable for Metal and wood Machining

Hardness : 92.6 HRA

Teeth : 72T

Tungsten carbide round cutting saw blades

Most of the saw cutters are made of the same kind of high speed steel, carbide and other materials. Compared with high speed steel, the carbide has higher hardness, stronger cutting force, higher speed and feed rate, and higher productivity.

Widely used in: glasses, watches, machinery, electronics, motors and other industries

Advantages of Tungsten carbide round cutting saw blades, carbide saw cutters

1. With submicron grain size ,Good wear-resistent,long service life.

2. With strict tolerance extent control

3. Enjoy excellent wear resistance & high toughnes

4. A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure meterial reliability

5. We carefully select the grade required for optimal cutting performance based on years of experience in the field

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

Tool material composition:

C) TRS greater than or equal to 3800 N/mm²;

Şereketde poroşok çig malyny taýýarlamakdan, galyndy ýasamakdan, basmakdan, basyşy süzmekden, üwemekden, örtmekden we örtükden başlap, pyçak öndürmek prosesi enjamlaryny öndürmek liniýasy bar. Esasy materialyň, çukuryň gurluşyna, karbid NC goýmalarynyň takyk emele gelmegine we ýerüsti örtügine ünsi jemleýär we karbid NC goýmalarynyň işleýiş netijeliligini, hyzmat ediş möhletini we beýleki kesiş aýratynlyklaryny yzygiderli ýokarlandyrýar. On ýyldan gowrak ylmy gözleglerden we innowasiýalardan soň, kompaniýa birnäçe garaşsyz esasy tehnologiýalary özleşdirdi, garaşsyz gözleg we dizaýn mümkinçiliklerine eýe we her bir müşderi üçin aýratyn önüm öndürip biler.