- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

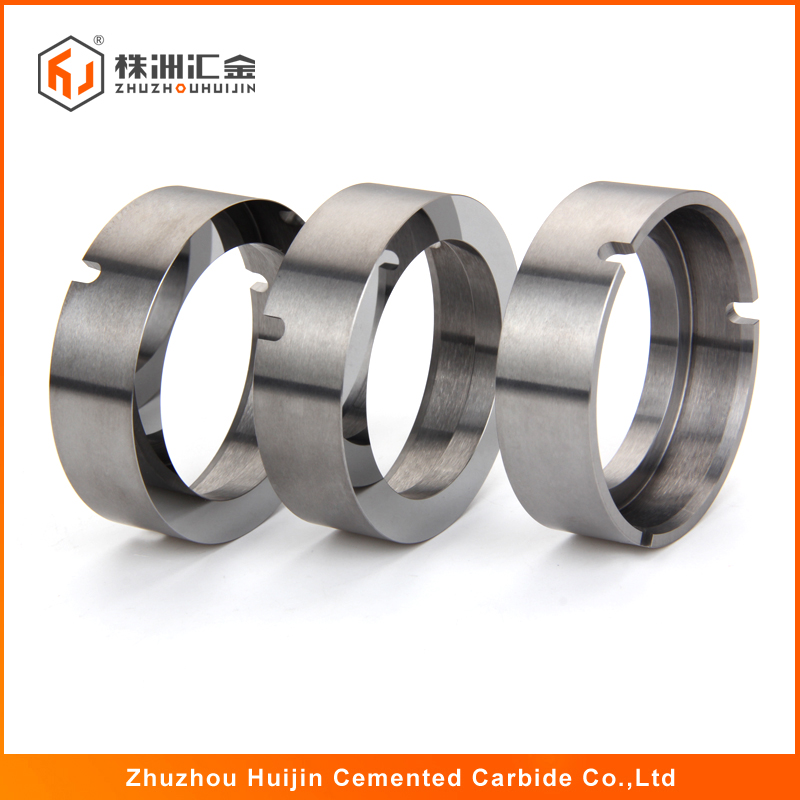

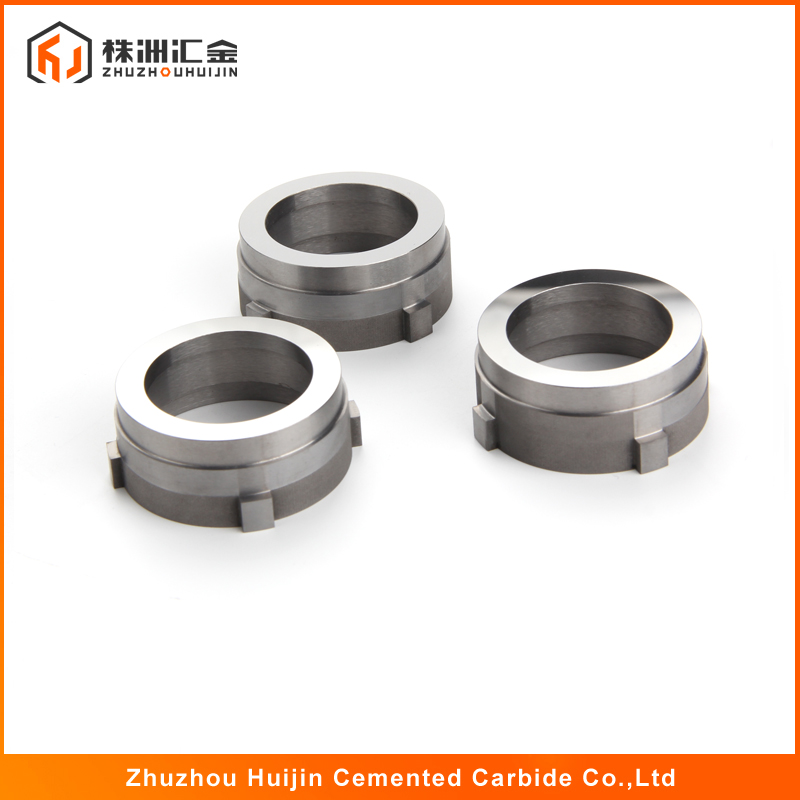

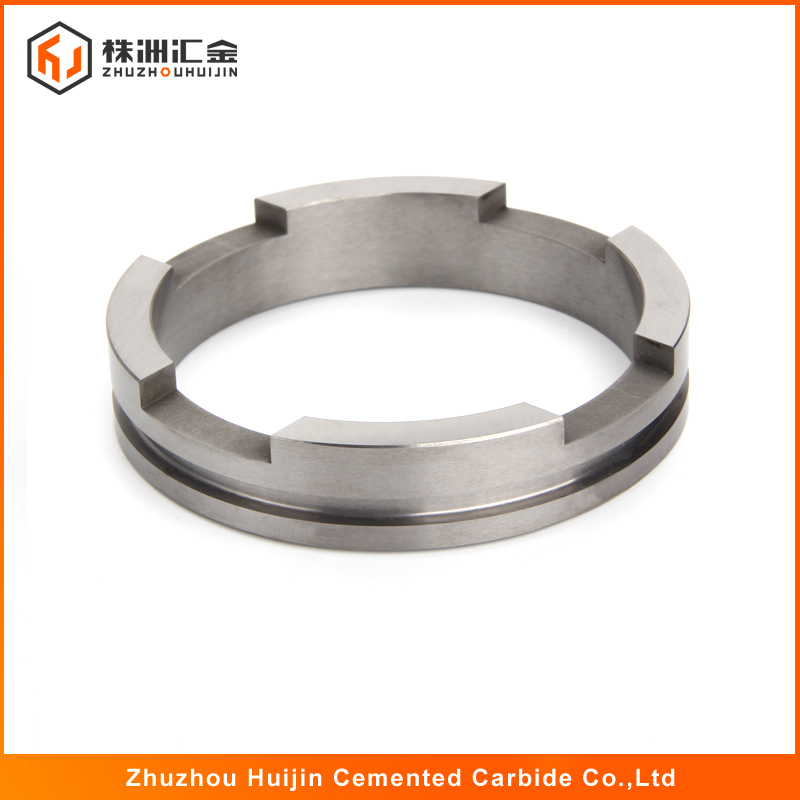

tungsten Carbide mechanical seal ring

YN6 Grinding Tungsten Carbide Ring - Cemented Mechanical Seal Ring

YN6 YN8 Face Seal /staionary Seal Ring

TC ring for mechanical seal

Nickel tungsten carbide mechanical seal ring

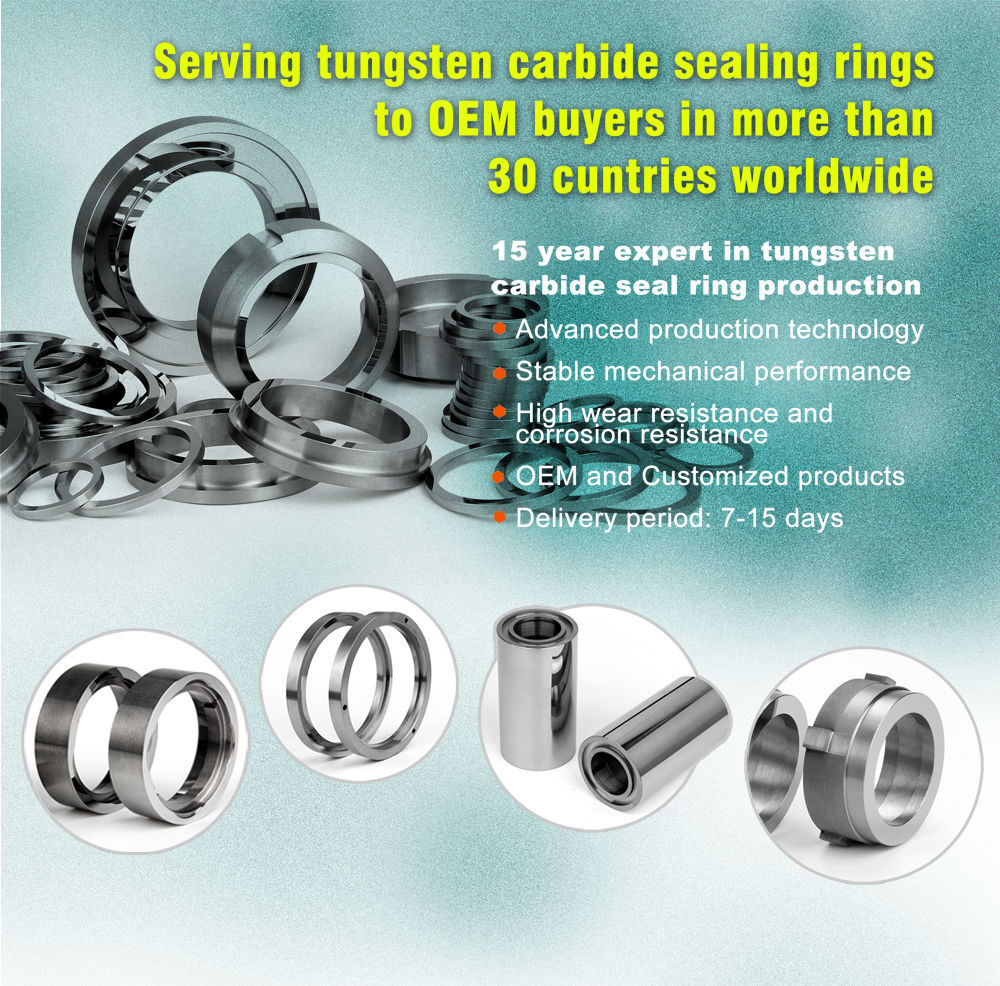

product information

Tungsten Carbide Seal Rings.

Carbide seal ring use tungsten carbide powder as raw material, adding suitable amount of cobalt powder and nickel powder as

binder, through a certain mold pressed into the ring, and finally sintered in the vacuum furnace or hydrogen reduction furnace.

Tungsten carbide seal rings are the most basic material in friction materials, and they are widely used as essential components of

seals. In addition, the seal rings is also widely used in the petrochemical industry due to its excellent wear resistance and corrosion resistance.

Precision wear-resistant tungsten carbide mechanical sealing

High-machining accuracy

High-strength, -hardness, -temperature-, corrosion-resistance

Long-time operating without wear

Long service life (up to 20000 hours)

We provide a wide range of tungsten carbide Mechanical Seal in different dimensions and shapes,pls contact us for the details.

Other grades can be offered as per customers'requirements.

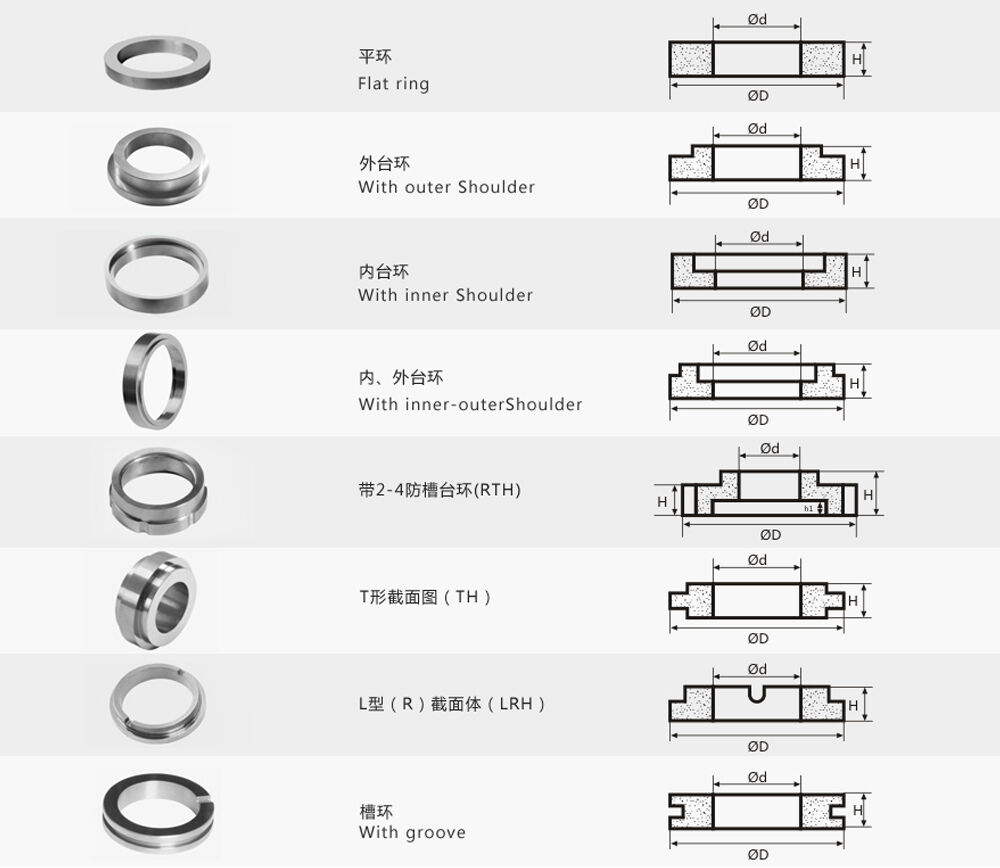

product type

Our services

Supply sintered and finish products.

Material covers nickel binder, cobalt binder and silicone carbide, carbon.

Both standard and non-standard parts according to the customer's drawings or samples are all available from us.

Huijin carbide have R and D department we can help you to choose and develop best grade depend on working service condition.

One piece can also be customized.

product show

Application:

Tungsten carbide seal ring face is a very versatile seal face used for mechanical sealing. It is a circle where rotary and stationary seal ring contacts, so that liquid won't leak out through. It widely used for Pumps, Compressors, Agitators, Oil Refineries, Petrochemical plants, Fertilizer Plants, and Medical Industries.

| Grade | Main chemical component (%) | Bending strength | Hardness | Density | Liner bulge Modulus | Application recommend | ||

| WC | Co | Ni | (>N/mm2) | (>HRA) | (g/cm3) | (10-6/k) | No magnetic alloy .Oil,Sewerage,Acid,alkili,Fat, | |

| YN6 | 94 | \ | 6 | 1500 | 89 | 14.5-14.9 | 5.2 | |

| YN8 | 92 | \ | 8 | 1650 | 88 | 14.4-14.8 | 5.3 | |

| YN10 | 90 | \ | 10 | 2100 | 87 | 14.5-14.9 | 5.3 | |

| YG6 | 94 | 6 | \ | 1550 | 89.5 | 14.7-15.1 | 5 | |

| YG8 | 92 | 8 | \ | 1700 | 89 | 14.6-14.9 | 5.1 | Oil,Sewerage,soft,Acid,alkili,Fat,fluidifyHydrocarbon,medium With Grain |

| YG15 | 85 | 15 | \ | 2500 | 87 | 13.9-14.2 | 6.3 | Gas seal of compressor |

Necessary information required for accurate quotation:

Specification ( like OD*ID*Length size,shape,angle etc.)

Surface condition: sintered blank or fine grinding.

Tolerance on dimension ( if you have).

If you have detail drawing contain all above information ,you can send drawing to us Tungsten carbide grade, or chemical composition.

If you are not quite clear about which tungsten carbide grade is suitable, please provide us the applications,we will suggest suitable grade base on your application .

Kampuni ina laini kamili ya utengenezaji wa vifaa vya utengenezaji wa vifaa kutoka kwa utayarishaji wa malighafi ya unga, kutengeneza ukungu, kukandamiza, kuweka shinikizo, kusaga, kupaka na kupaka baada ya matibabu. Inazingatia utafiti na uvumbuzi wa nyenzo za msingi, muundo wa groove, uundaji wa usahihi na mipako ya uso ya kuingizwa kwa carbudi NC, na inaboresha mara kwa mara ufanisi wa machining, maisha ya huduma na mali nyingine za kukata za kuingiza carbudi NC. Baada ya zaidi ya miaka kumi ya utafiti wa kisayansi na uvumbuzi, kampuni ina mastered idadi ya teknolojia ya msingi huru, ina kujitegemea R & D na kubuni uwezo, na inaweza kutoa customized uzalishaji kwa kila mteja.