- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

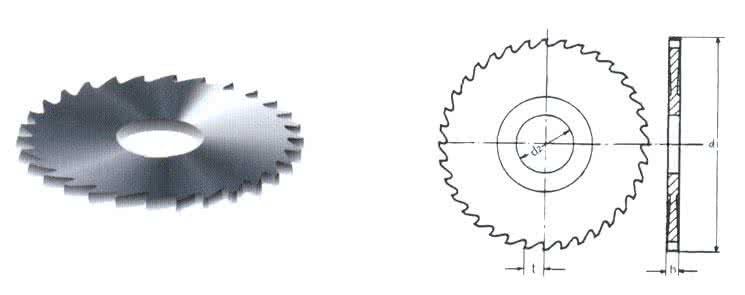

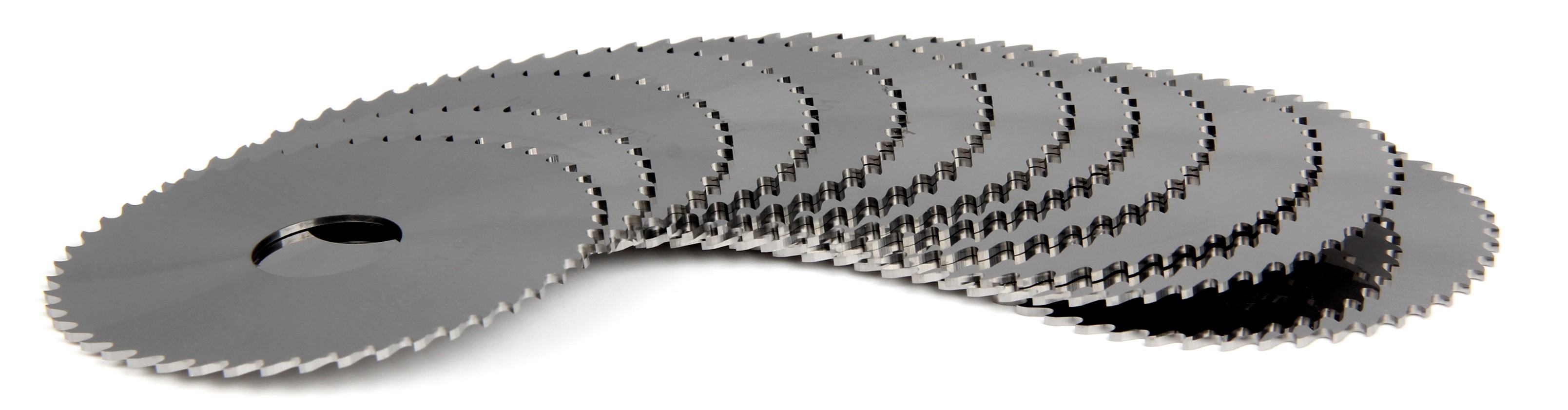

Carbide saw blade cutter for aluminum cutting

Carbide saw blade cutter

Sizes :60*16*1.0*48T

Suitable for aluminum cutting

Hardness : 92.6 HRA

Teeth : 48T

Carbide saw blade cutter for aluminum cutting

Most of the saw cutters are made of the same kind of high speed steel, carbide and other materials. Compared with high speed steel, the carbide has higher hardness, stronger cutting force, higher speed and feed rate, and higher productivity.

Widely used in: glasses, watches, machinery, electronics, motors and other industries

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

C) TRS greater than or equal to 3800 N/mm²;

Khamphani e na le mohala o felletseng oa tlhahiso ea lisebelisoa tsa lehare ho tloha ho tokiso ea lihlahisoa tse tala, ho etsa hlobo, ho hatella, ho sila ka khatello, ho sila, ho roala le ho roala ka mor'a kalafo. E shebane le lipatlisiso le boqapi ba lisebelisoa tsa motheo, sebopeho sa groove, ho etsoa ka nepo le ho roala ka holim'a li-carbide NC, 'me e lula e ntlafatsa ts'ebetso ea machining, bophelo ba ts'ebeletso le lisebelisoa tse ling tsa ho itšeha tsa carbide NC inserts. Ka mor'a lilemo tse fetang leshome tsa lipatlisiso tsa saense le mekhoa e mecha, k'hamphani e tseba mekhoa e mengata ea motheo e ikemetseng, e na le R&D e ikemetseng le bokhoni ba ho qapa, 'me e ka fana ka tlhahiso e ikhethileng bakeng sa moreki e mong le e mong.