- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

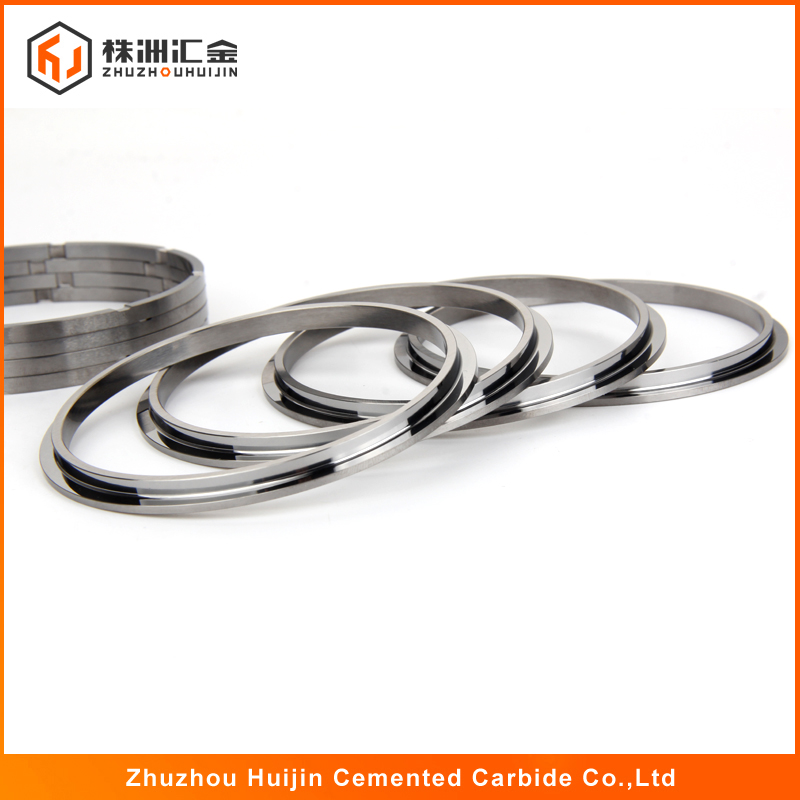

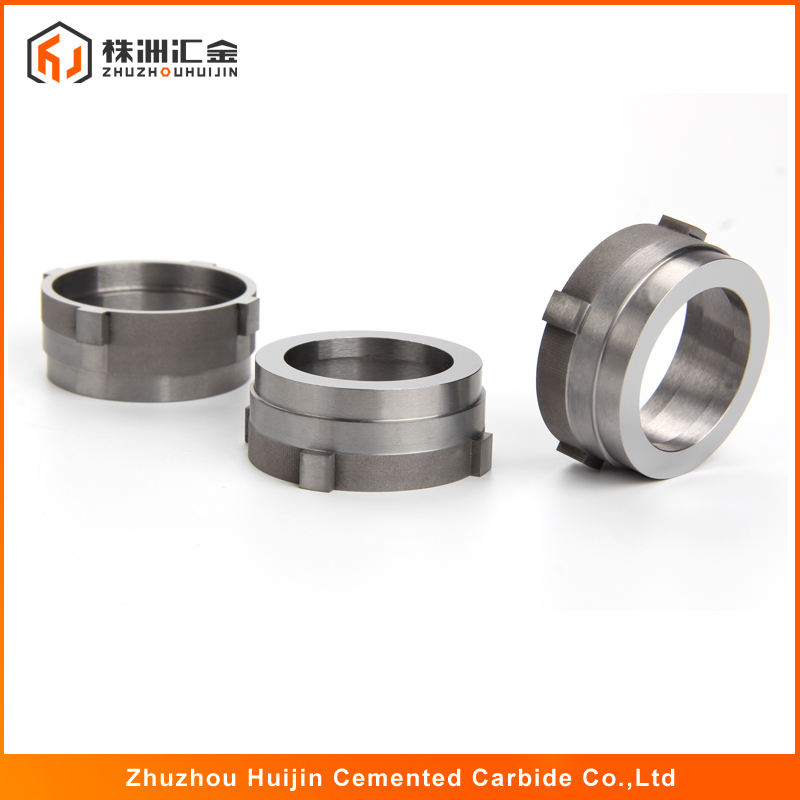

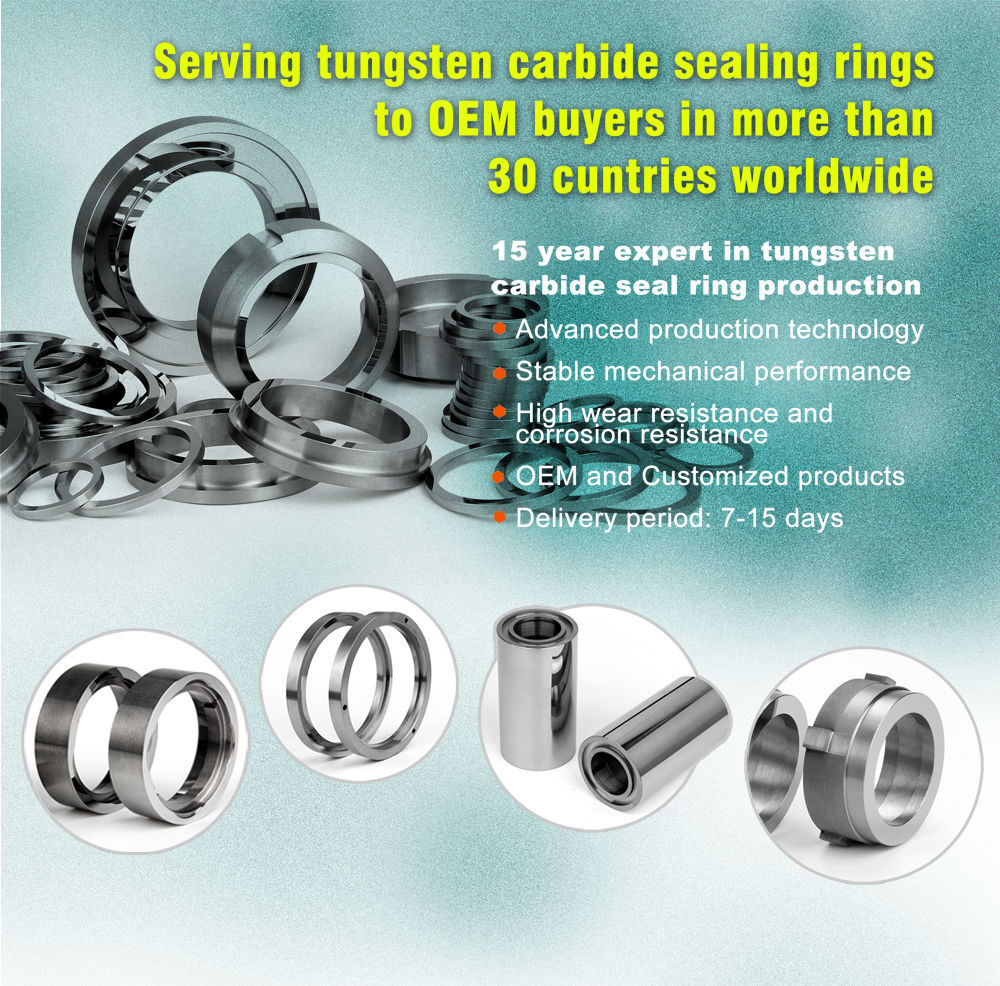

tungsten Carbide mechanical seal ring

High Quality Tungsten Carbide Seal Ring With Excellent Wear resistance

anti-corrosion erosion tungsten carbide seal ring

TC ring for mechanical seal

Nickel tungsten carbide mechanical seal ring

product information

Tungsten Carbide Seal Rings.

Carbide seal ring use tungsten carbide powder as raw material, adding suitable amount of cobalt powder and nickel powder as

binder, through a certain mold pressed into the ring, and finally sintered in the vacuum furnace or hydrogen reduction furnace.

Tungsten carbide seal rings are the most basic material in friction materials, and they are widely used as essential components of

seals. In addition, the seal rings is also widely used in the petrochemical industry due to its excellent wear resistance and corrosion resistance.

Precision wear-resistant tungsten carbide mechanical sealing

High-machining accuracy

High-strength, -hardness, -temperature-, corrosion-resistance

Long-time operating without wear

Long service life (up to 20000 hours)

We provide a wide range of tungsten carbide Mechanical Seal in different dimensions and shapes,pls contact us for the details.

Other grades can be offered as per customers'requirements.

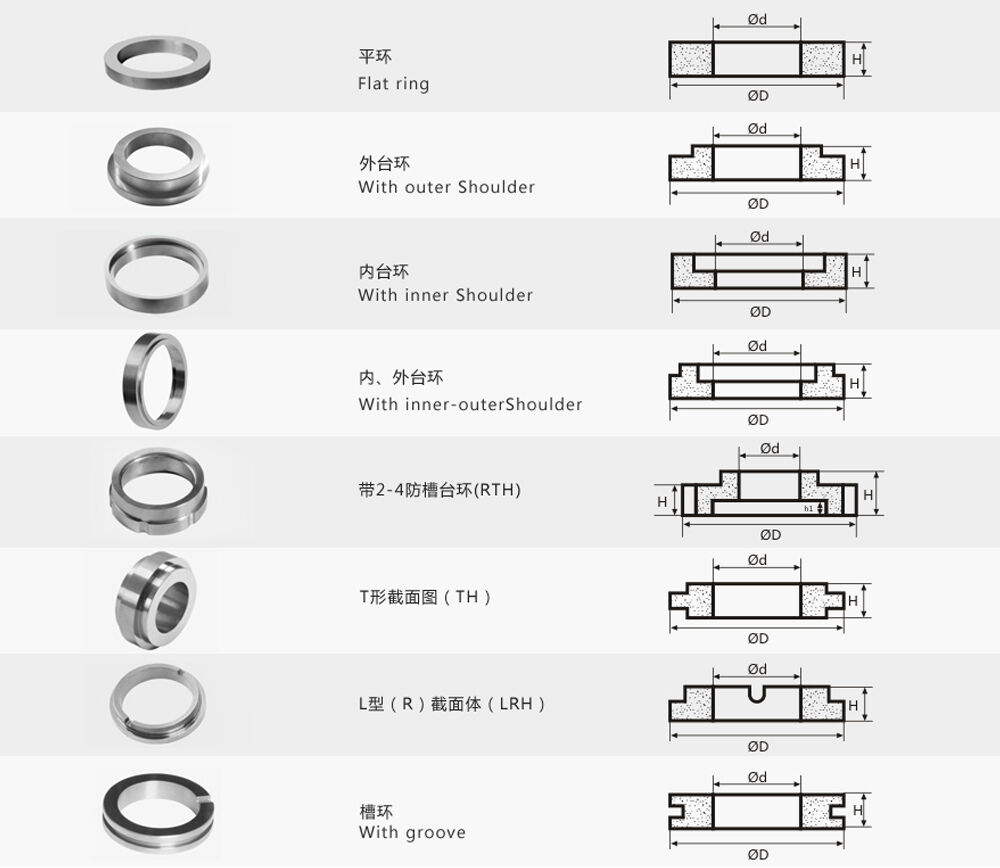

product type

Our services

Supply sintered and finish products.

Material covers nickel binder, cobalt binder and silicone carbide, carbon.

Both standard and non-standard parts according to the customer's drawings or samples are all available from us.

Huijin carbide have R and D department we can help you to choose and develop best grade depend on working service condition.

One piece can also be customized.

product show

Application:

Tungsten carbide seal ring face is a very versatile seal face used for mechanical sealing. It is a circle where rotary and stationary seal ring contacts, so that liquid won't leak out through. It widely used for Pumps, Compressors, Agitators, Oil Refineries, Petrochemical plants, Fertilizer Plants, and Medical Industries.

| Grade | Main chemical component (%) | Bending strength | Hardness | Density | Liner bulge Modulus | Application recommend | ||

| WC | Co | Ni | (>N/mm2) | (>HRA) | (g/cm3) | (10-6/k) | No magnetic alloy .Oil,Sewerage,Acid,alkili,Fat, | |

| YN6 | 94 | \ | 6 | 1500 | 89 | 14.5-14.9 | 5.2 | |

| YN8 | 92 | \ | 8 | 1650 | 88 | 14.4-14.8 | 5.3 | |

| YN10 | 90 | \ | 10 | 2100 | 87 | 14.5-14.9 | 5.3 | |

| YG6 | 94 | 6 | \ | 1550 | 89.5 | 14.7-15.1 | 5 | |

| YG8 | 92 | 8 | \ | 1700 | 89 | 14.6-14.9 | 5.1 | Oil,Sewerage,soft,Acid,alkili,Fat,fluidifyHydrocarbon,medium With Grain |

| YG15 | 85 | 15 | \ | 2500 | 87 | 13.9-14.2 | 6.3 | Gas seal of compressor |

Necessary information required for accurate quotation:

Specification ( like OD*ID*Length size,shape,angle etc.)

Surface condition: sintered blank or fine grinding.

Tolerance on dimension ( if you have).

If you have detail drawing contain all above information ,you can send drawing to us Tungsten carbide grade, or chemical composition.

If you are not quite clear about which tungsten carbide grade is suitable, please provide us the applications,we will suggest suitable grade base on your application .

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.