- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

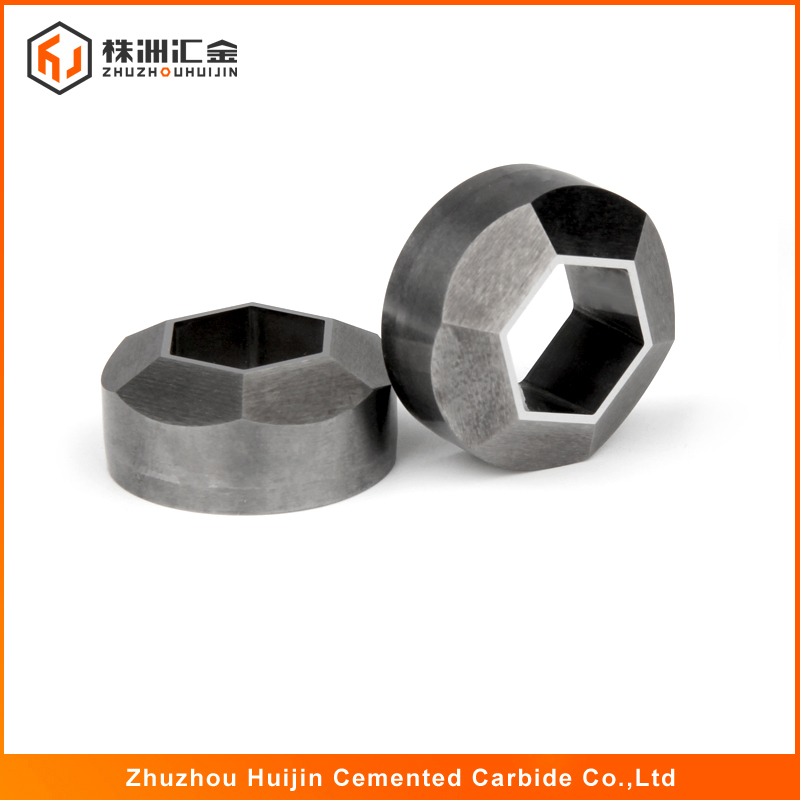

Tungsten carbide cold heading stamping dies

Customized carbide part for guiding purpose Φ138×Φ50×16T

Customized carbide part for guiding purpose

customized non standard die

tungsten carbide cold forging dies

Customized carbide part for guiding purpose Φ138×Φ50×16T

Tungsten carbide roller ring is made by tungsten carbide which could improve the mechanical

characteristics of the cold rolled wire. They are used for removing any bends, irregularities, and mills left in

the material that is being processed. Also could be used for wire straightening it could ensures that the

final wire or rod will be consistent and free off defects.

Advantages

1. Sizes produce according to customer's size

2. 10 - 20 times life time longer than steel roller ring. Saving maintenance time and cost.

3. High wear resistance.

4. High heat resistance.

5. V – U and custom straightening grooves

6.Provide all kinds of non-standard series of products according to the users' requirements.

Tungsten carbide has high hardness, wear resistance, strength and toughness, good heat resistance

, corrosion resistance and a series of excellent properties, especially its high hardness and wear

resistance, even in 500℃ temperature is basically unchanged, still has a very high hardness in 1000℃

product show

Necessary information required for accurate quotation :

Specification ( like OD*ID*Length size,shape,angle etc.)

Surface condition: sintered blank or fine grinding

Tolerance on dimension ( if you have)

If you have detail drawing contain all above information ,you can send drawing to us Tungsten carbide grade, or chemical composition.

If you are not quite clear about which tungsten carbide grade is suitable, please provide us the applications,we will suggest suitable grade base on your

The company has a complete blade manufacturing process equipment production line from powder raw material preparation, mold making, pressing, pressure sintering, grinding, coating and coating post-treatment. It focuses on the research and innovation of the base material, groove structure, precision forming and surface coating of carbide NC inserts, and constantly improves the machining efficiency, service life and other cutting properties of carbide NC inserts. After more than ten years of scientific research and innovation, the company has mastered a number of independent core technologies, has independent R&D and design capabilities, and can provide customized production for each customer.