- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

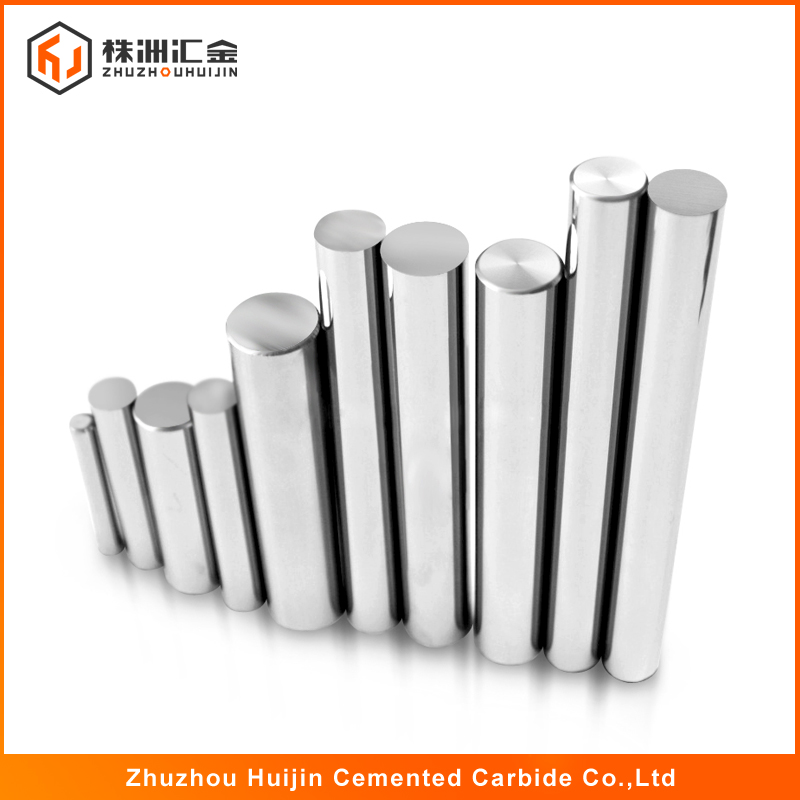

Carbide Solid Round Bar

12% Cobalt HRA 92.6 Tungsten Carbide Rods

Carbide Tungsten Rod for making cutting tools

High Hardness Carbide Solid Round Bar

Carbide Polished Grinding Round Bar

Small Diameter Tungsten carbide Rods

Product Description

Tungsten carbide(also named as cemented carbide) a kind of material made from combination of tungsten and

carbon(with formula WC) with cobalt binder,it could keep stable property under high temperature 800ºC with

high compressive strength,high hardness and strong resistance to wear,which make tungsten carbide cutting tools

a perfect choice for many industrial needs.

Tungsten carbide rod is the preferred material for metal cutting tool manufacturing, widely used in the industries which has high

requirements for wear-resistance, corrosion-resistance and high-temperature resistance. It has a lot of outstanding performance.

1. 100% raw material

2. With strict tolerance extent control

3. Excellent wear resistance & high toughness

4. Have very good thermal & chemical stability

5. Anti-deformation & deflection

6. A special Hot Isostatic Press (HIP) process

7. Customized order is welcomed.

Application of Carbide rods and bars

Carbide rods are mainly used for drill bits, end-milling cutters and winches. It can also be used for cutting, stamping

and measuring tools. It is used in paper, packaging, printing, non-ferrous metal processing industry. In addition,

it is widely used in machining high speed steel cutters, carbide milling cutters, cemented carbide cutters, NAS

cutting tools, aviation cutters, cemented carbide bits, milling cutter core bits, high speed steel, taperd milling cutters,

metric milling cutters, micro End milling cutters, hinge pilot, electronic tool,

carbide rotary file, cemented carbide tool, etc.

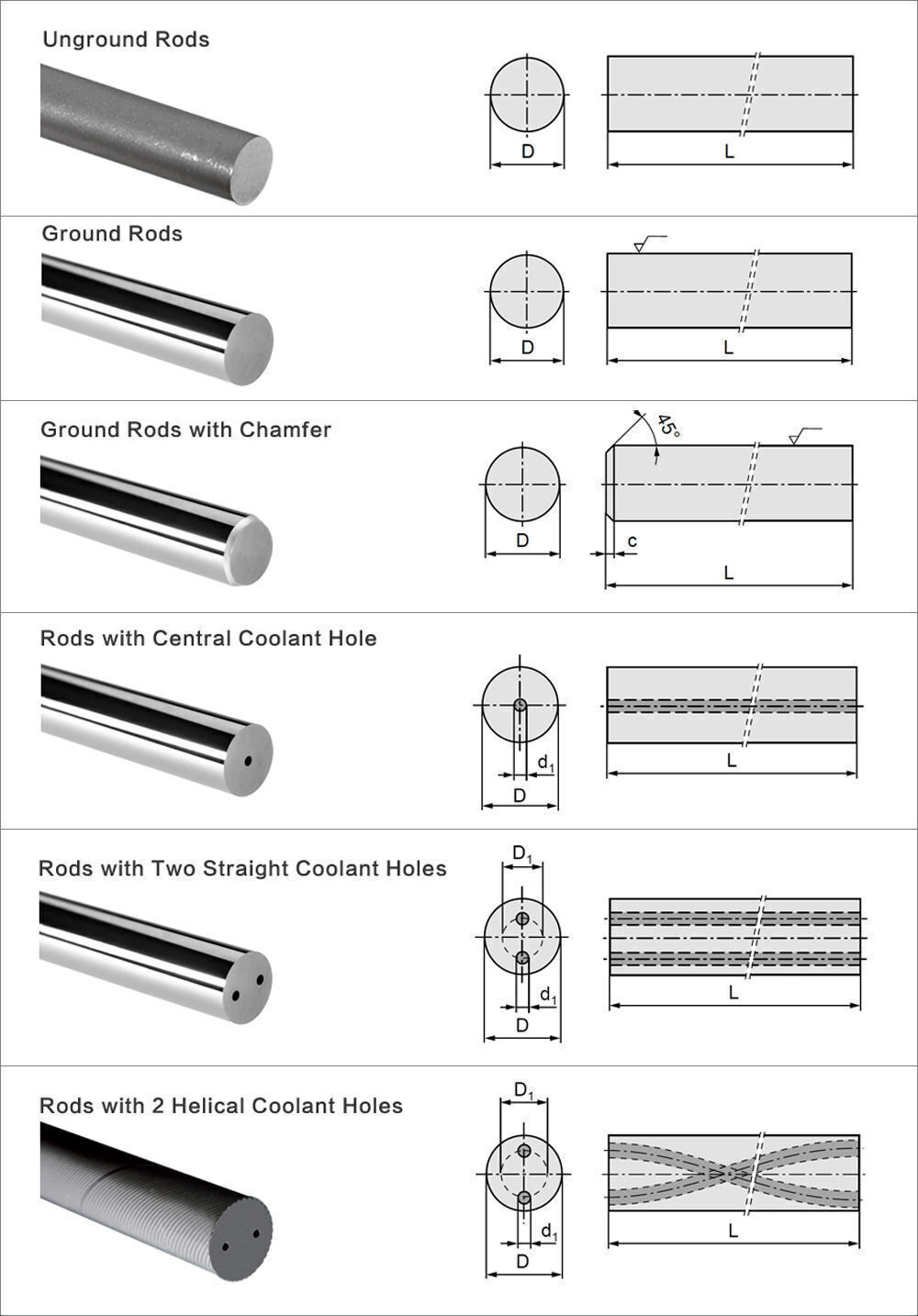

Main types of the carbide rods

| Grade | ISO Application Area | Grain Size (μ m) | Cobalt Content (%) | Hardness (HRA) | Density (g/cm³) | T.R.S (N/mm³) | Grades Applications recommmended |

| HY06A | K05-K1 0 | 0.4 | 6.0 | 94.0 | 14.80 | 3800 | Ultrafine grain size,with amazing wear resistance.High wearresistance endmill and engraving tools are recommended.Suitable for cutting PCB and composite material. |

| HY09A | K05-K20 | 0.3 | 9.0 | 93.5 | 14.45 | 4000 | High wear resistance and strength, suitable for high hard materials (HRC55 or above) finishing, aluminum alloy, bowl alloy, stainless steel, superalloy and other difficult materials (composite wood) high light surface treatment. |

| HY12A | K20-K40 | 0.4 | 12.0 | 92.5 | 14.10 | 4200 | Ultrafine grain size,higher Co content;with excellent hardnessand toughness.Endmill and reamer are recommended.Excellent performance for finishing.Especially suitable forcutting steel(HRC:45-59),Al alloy and Ti alloy. |

| HY10 | K20-K40 | 0.6 | 10.0 | 91.7 | 14.40 | 4000 | Drill and endmill are recommended.Suitable for cutting generalsteel (HRC<48)、grey cast iron、stainless steel and heatresistant alloy. |

| HY10A | K20-K40 | 0.5 | 10.3 | 92.3 | 14.30 | 4200 | Drill and endmill are recommended.Especially suitable forcutting stainless steel,heat resistant alloy,cast iron. |

| HY12 | K20-K40 | 0.5 | 12.0 | 92.0 | 14.10 | 4200 | Endmill and reaming for high hardness material arerecommended.Sutable for cast iron、stainless steel |

| HY06 | K10 | 0.6 | 6.0 | 93.3 | 14.90 | 3800 | Endmill and reaming for high hardness material arerecommended.Sutable for cast iron、stainless steel |

| HY15 | K30-K40 | 1.5 | 15.0 | 87.6 | 14.0 | 4000 | Suitable for making punching of moulds、tools and anti-vibration boring bar etc. |

| Diameter | Tolerance in ground | Total length | Tolerance in length |

| D 2 mm | h5/h6 | 330mm | +0, +5mm |

| D 3 mm | 330mm | +0, +5mm | |

| D 4 mm | 330mm | +0, +5mm | |

| D 5 mm | 330mm | +0, +5mm | |

| D 6 mm | 330mm | +0, +5mm | |

| D 7 mm | 330mm | +0, +5mm | |

| D 8 mm | 330mm | +0, +5mm | |

| D 9 mm | 330mm | +0, +5mm | |

| D 10 mm | 330mm | +0, +5mm | |

| D 11 mm | 330mm | +0, +5mm | |

| D 12 mm | 330mm | +0, +5mm | |

| D 13 mm | 330mm | +0, +5mm | |

| D 14 mm | 330mm | +0, +5mm | |

| D 15 mm | 330mm | +0, +5mm | |

| D 16 mm | 330mm | +0, +5mm | |

| D 17 mm | 330mm | +0, +5mm | |

| D 18 mm | 330mm | +0, +5mm | |

| D 19 mm | 330mm | +0, +5mm | |

| D 20 mm | 330mm | +0, +5mm | |

| D 21 mm | 330mm | +0, +5mm | |

| D 22 mm | 330mm | +0, +5mm | |

| D 23 mm | 330mm | +0, +5mm | |

| D 24 mm | 330mm | +0, +5mm | |

| D 25 mm | 330mm | +0, +5mm | |

| D 26 mm | 330mm | +0, +5mm | |

| D 27 mm | 330mm | +0, +5mm | |

| D 28 mm | 330mm | +0, +5mm | |

| D 29 mm | 330mm | +0, +5mm | |

| D 30 mm | 330mm | +0, +5mm | |

| D 31- D 50mm | 330mm | +0, +5mm |

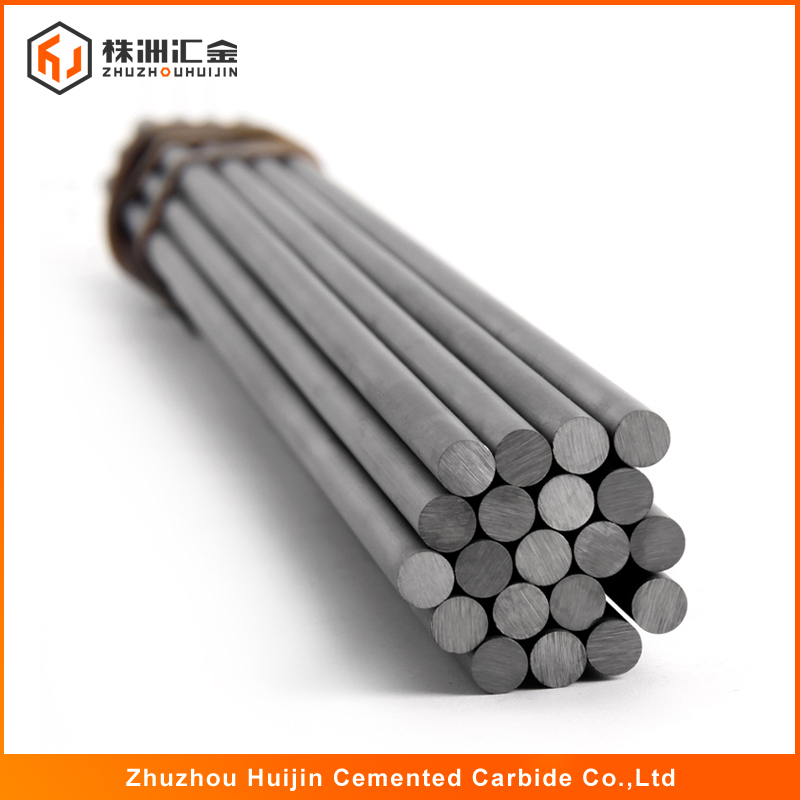

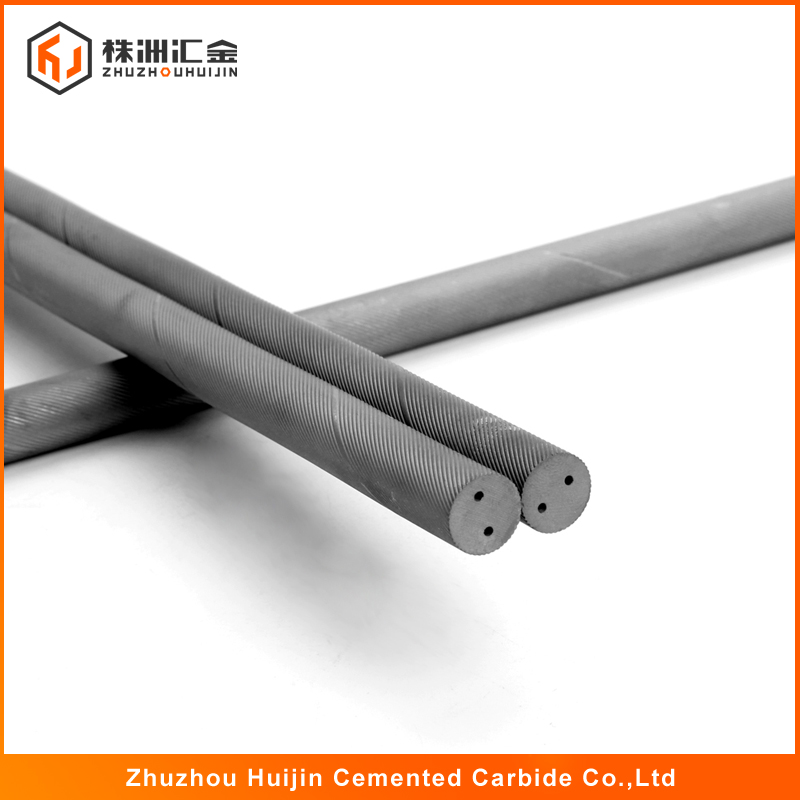

We provide a wide range of tungsten carbide rods in different dimensions, like solid carbide rods, rod with single straight hole, double holes and also twisted holes.

Our advantages

Professional team for production: Have more than 10 years experience for production on carbide filed.

Fast delivery based on high production capability.

Strict quality control system: Ensure our product in good and stable quality.

Rich experience on customized products.

Technical support: Help you get the best solution.

Uzņēmumam ir pilna asmeņu ražošanas procesa iekārtu ražošanas līnija no pulvera izejvielu sagatavošanas, veidņu izgatavošanas, presēšanas, spiediena saķepināšanas, slīpēšanas, pārklāšanas un pārklāšanas pēcapstrādes. Tas ir vērsts uz karbīda NC ieliktņu pamatmateriāla, rievu struktūras, precīzas formēšanas un virsmas pārklājuma izpēti un inovācijām, kā arī pastāvīgi uzlabo apstrādes efektivitāti, kalpošanas laiku un citas karbīda NC ieliktņu griešanas īpašības. Pēc vairāk nekā desmit gadu ilgas zinātniskās izpētes un inovācijas uzņēmums ir apguvis vairākas neatkarīgas pamattehnoloģijas, tam ir neatkarīgas pētniecības, izstrādes un dizaina iespējas, un tas var nodrošināt pielāgotu ražošanu katram klientam.