- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

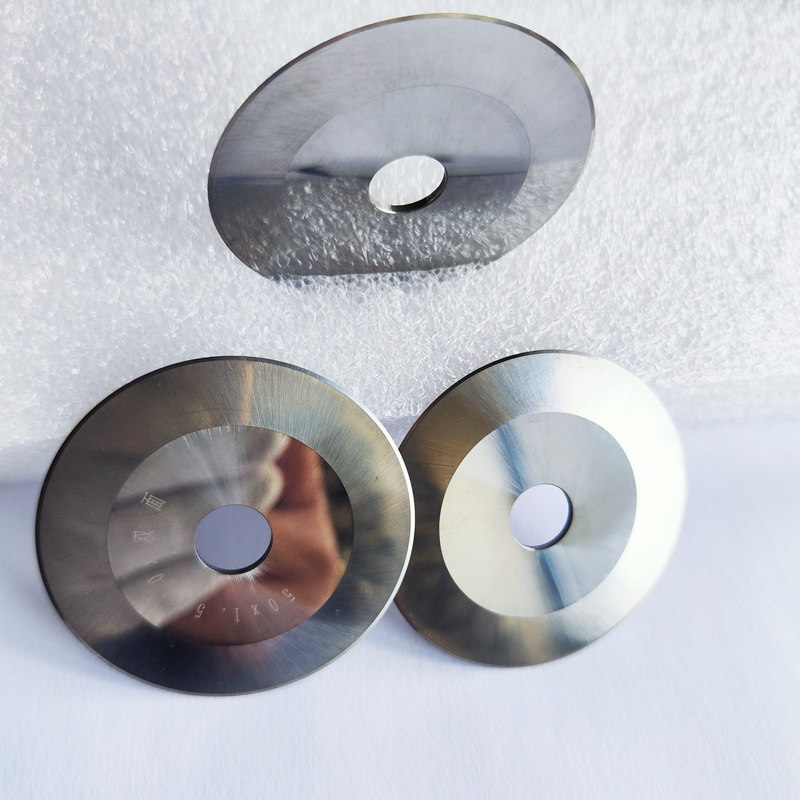

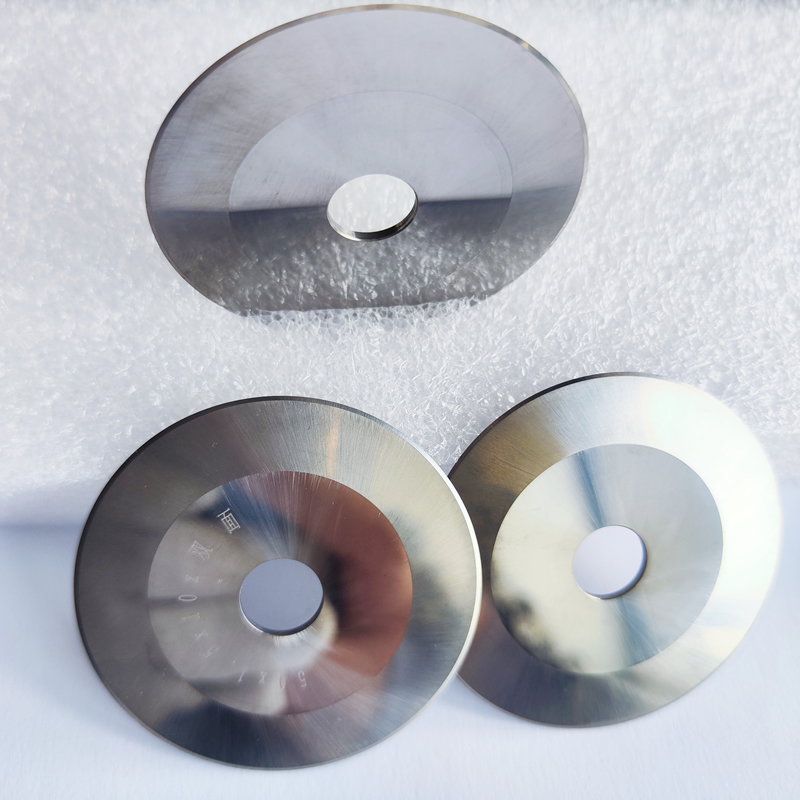

circular ultra fine sub micron grain cemented carbide blades

circular ultra fine sub micron grain cemented carbide blades

Service : OEM and ODM

Application: weft cutter of hard yarn for weaving loom machines

Surface: with superior razor sharp edge quality and mirror surface and edge polish

hardness: 92 HRA

circular ultra fine sub micron grain cemented carbide blades

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

In addition,we can provide the grinding wheel for the blade,slotting blade and others blade used for carton ,tobacco machinery.

material grade :

| Grade | Grain size (um) | Cobalt content (100%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm2) |

| YG6X | 0.8-1.2 | 6 | 14.8 | 91 | 2000 |

| YG10X | 0.8-1.2 | 10 | 14.42 | 91.8 | 4000 |

| YG12X | 0.8-1.2 | 12 | 14.5 | 89.5 | 2600 |

| Material grade | Tungsten Carbide YG10X, YG13X, OEM | |||

| Thickness | 0.2-6mm or customized | |||

| Flatness | 0.003mm | |||

| Type of edge | single edge, double edge | |||

| HRA | 85-93 | |||

| Straightness | <0.1 | |||

| Surface roughness | Ra0.2 | |||

| Laser engraving | Done as requirement | |||

| Package | 4 pcs/set,Simple packing/Plastic box packing/Blister packing | |||

| Main Size | OD(mm) | ID(mm) | Thickness(mm) | Cutting Edge |

| 300 | 112 | 1.4 | double | |

| 280 | 168 | 1.4 | double | |

| 265 | 112 | 1.3 | double | |

| 260 | 168 | 1.4 | double | |

| 260 | 140 | 1.4 | double | |

| 240 | 132 | 1.2 | double | |

| 230 | 110 | 1.3 | double | |

| 140 | 46 | 0.5 | single | |

| 100 | 16 | 0.3 | single | |

| 85 | 16 | 0.25 | single | |

| 60 | 19 | 0.27 | single | |

| Size | Can be customized according to customer requirements | |||

| Advantages | 1, High quality raw materials. | |||

| 2. Durable & Long service life. | ||||

| 3. High precision. | ||||

| 4. Nice and solid packaging. | ||||

| 5. Excellent weather resistance and waterproof. | ||||

| Application | For paperboard/paper/cardboard/carton/Tobacco machine to cut. | |||

D'Firma huet eng komplett Blade Fabrikatioun Prozess Ausrüstung Produktioun Linn aus Pudder Rohmaterial Virbereedung, Ofdréck maachen, Pressen, Drock sinteren, Schleifen, Beschichtung a Beschichtung Post-Behandlung. Et konzentréiert sech op d'Fuerschung an d'Innovatioun vum Basismaterial, d'Groovestruktur, d'Präzisiounsformung an d'Uewerflächbeschichtung vu Carbide NC-Inserts, a verbessert permanent d'Maschinneffizienz, Liewensdauer an aner Schneideigenschaften vun Carbide NC-Inserts. No méi wéi zéng Joer wëssenschaftlech Fuerschung an Innovatioun, huet d'Firma eng Rei vun onofhängege Kär Technologien beherrscht, huet onofhängeg R & D an Design Kënnen, a kann personaliséiert Produktioun fir all Client bidden.