- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

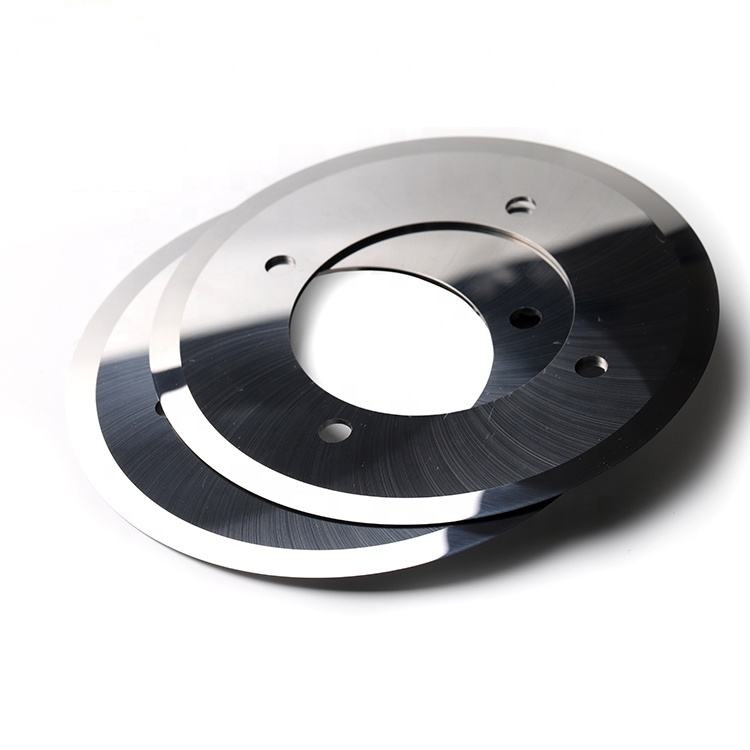

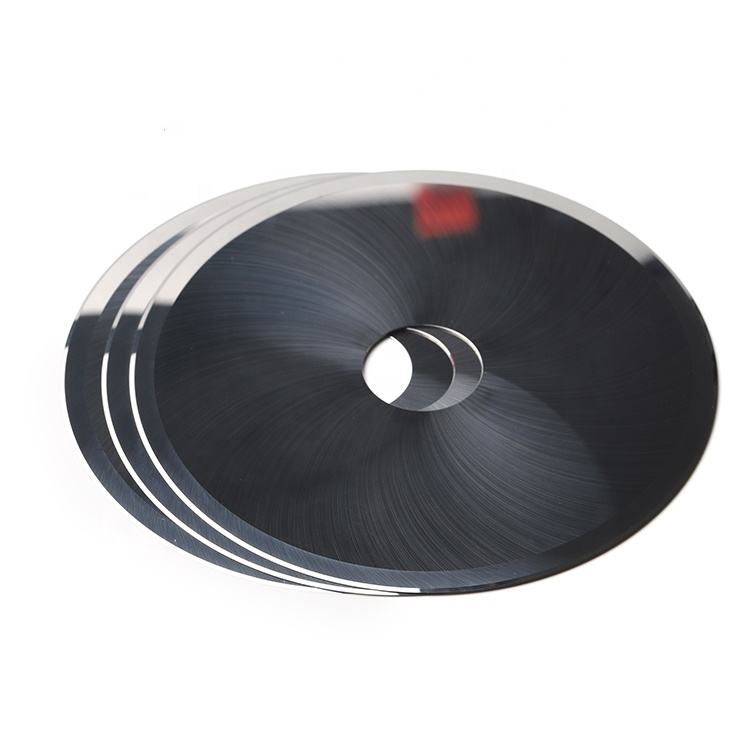

Tungsten Carbide Corrugated Cardboard cutter

Corrugated Cardboard cutter

Service : OEM and ODM

Application: corrugated slitter scorer machine

Surface: grinding and polishing to mirror

Working life: 7-9 millions meters

Tungsten Carbide Corrugated Cardboard cutter

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

In addition,we can provide the grinding wheel for the blade,slotting blade and others blade used for carton ,tobacco machinery.

material grade :

| Grade | Grain size (um) | Cobalt content (100%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm2) |

| YG6X | 0.8-1.2 | 6 | 14.8 | 91 | 2000 |

| YG10X | 0.8-1.2 | 10 | 14.42 | 91.8 | 4000 |

| YG12X | 0.8-1.2 | 12 | 14.5 | 89.5 | 2600 |

| Material grade | Tungsten Carbide YG10X, YG13X, OEM | |||

| Thickness | 0.2-6mm or customized | |||

| Flatness | 0.003mm | |||

| Type of edge | single edge, double edge | |||

| HRA | 85-93 | |||

| Straightness | <0.1 | |||

| Surface roughness | Ra0.2 | |||

| Laser engraving | Done as requirement | |||

| Package | 4 pcs/set,Simple packing/Plastic box packing/Blister packing | |||

| Main Size | OD(mm) | ID(mm) | Thickness(mm) | Cutting Edge |

| 300 | 112 | 1.4 | double | |

| 280 | 168 | 1.4 | double | |

| 265 | 112 | 1.3 | double | |

| 260 | 168 | 1.4 | double | |

| 260 | 140 | 1.4 | double | |

| 240 | 132 | 1.2 | double | |

| 230 | 110 | 1.3 | double | |

| 140 | 46 | 0.5 | single | |

| 100 | 16 | 0.3 | single | |

| 85 | 16 | 0.25 | single | |

| 60 | 19 | 0.27 | single | |

| Size | Can be customized according to customer requirements | |||

| Advantages | 1, High quality raw materials. | |||

| 2. Durable & Long service life. | ||||

| 3. High precision. | ||||

| 4. Nice and solid packaging. | ||||

| 5. Excellent weather resistance and waterproof. | ||||

| Application | For paperboard/paper/cardboard/carton/Tobacco machine to cut. | |||

It bedriuw hat in folsleine produksjeline foar blêdproduksjeprosesapparatuer fan tarieding fan poedergrûnstoffen, skimmel meitsjen, drukken, druk sinterjen, slypjen, coating en neibehanneling fan coating. It rjochtet him op it ûndersyk en ynnovaasje fan de basis materiaal, groove struktuer, precision foarmjen en oerflak coating fan carbid NC Inserts, en hieltyd ferbetteret de Machtigingsformulier effisjinsje, libbensdoer en oare cutting eigenskippen fan carbid NC Inserts. Nei mear as tsien jier fan wittenskiplik ûndersyk en ynnovaasje, it bedriuw hat behearske in oantal ûnôfhinklike kearn technologyen, hat ûnôfhinklike R & D en design mooglikheden, en kin foarsjen maatwurk produksje foar elke klant.