- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

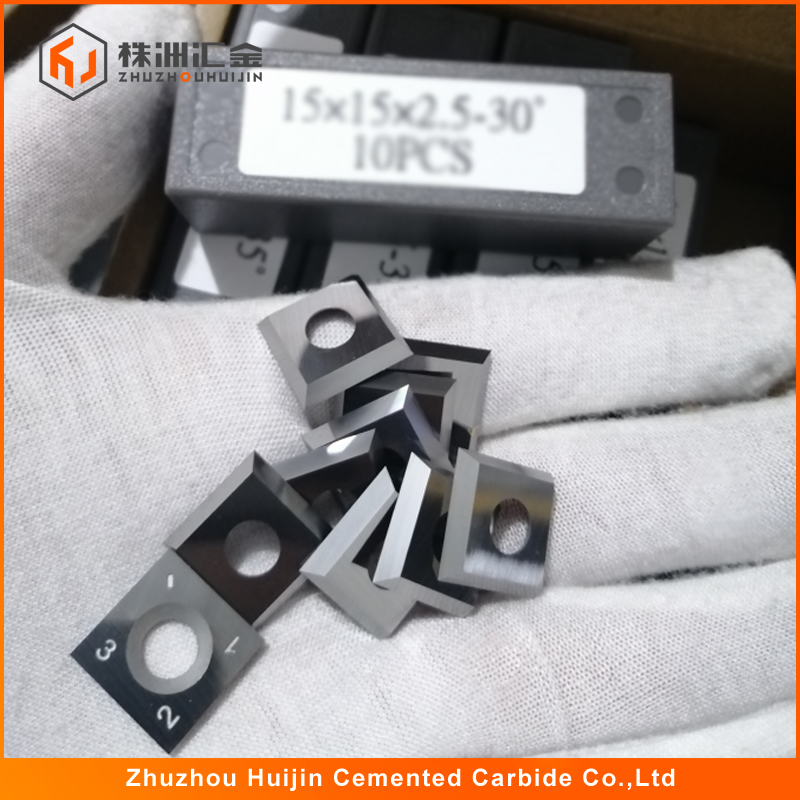

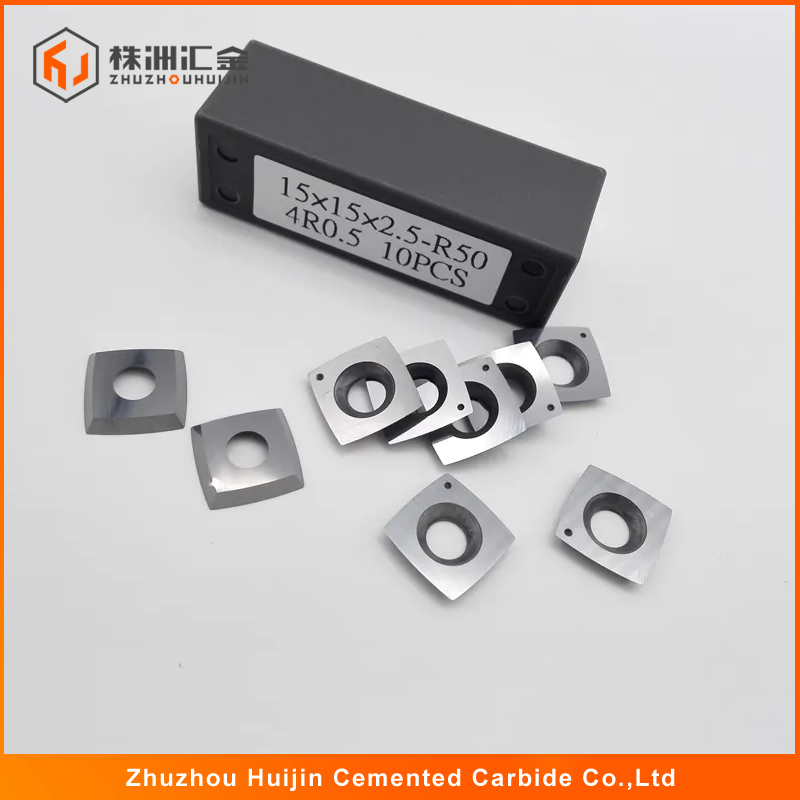

14*14*2 Tungsten Carbide Replacement Cutter Reversible Knives For Spiral Cutter Head Indexable knives

14*14*2 Tungsten Carbide Replacement Cutter Reversible Knives For Spiral Cutter Head Indexable knives

Sizes :14*14*2

Application: Wood Working

Material:Cemented carbide

Service : OEM and ODM

14*14*2 Tungsten Carbide Replacement Cutter Reversible Knives For Spiral Cutter Head Indexable knives

Products Description

We provide different types of carbide inserts for wood working, inculding inserts with 2 cutting edges and 4 cutting edges.we also can produce the wood working carbide parts based on your designs. Our wood working parts have very good finshing and long tool life, it will make your job easy and save your cost.

Our cutters are strictly inspected after each process, including body thickness, size, flatness, bore, angle, joint length, hardness and etc. We promise to ship 100% qualified product.

Application

1.Suitable for hard and soft wood

2.Strong and high precision cutting edge,easy to replace your jointers and planers

3.Smooth planing, 2 or 4 usable sides, all are of the same good performance

4.100% virgin tungsten carbide makes the longer life time

Product feature

1. Wear resistance with high toughness: resulting in increased tool life, reduction in number of tool changes, reduced grinding and lower production costs.

2. Resistant to corrosion: protection against chemical influences such as resin

3. Resistant to oxidation: protection against thermal influences

4. Resistant to abrasion: protection against mechanical wear

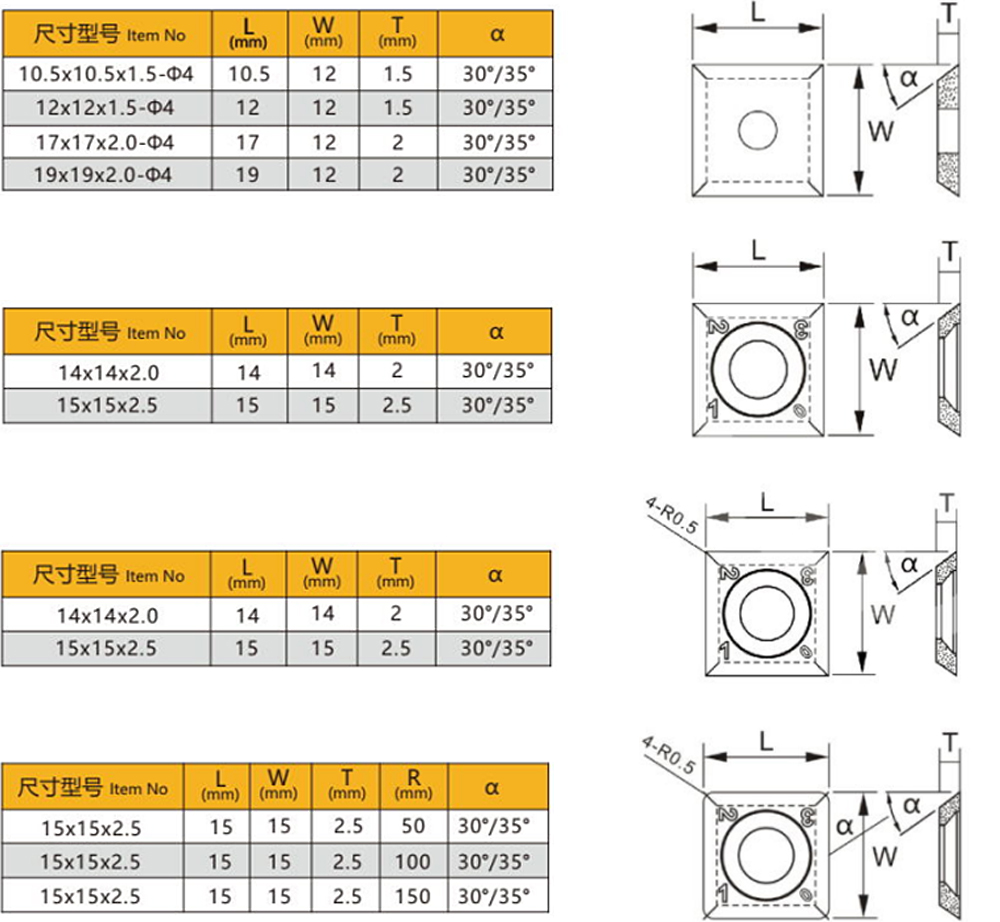

Sizes and drawing

Production as per customer’s drawing and requirements. Also we can select proper items according to buyer’s usage. Please advise your size and quantity for quotation. Other design you need, please sending us your picture or drawing, we will produce accordingly.

OEM service:

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Our OEM Service include (not limited to ):

1. Free design

2. Free samples test

3. Determination of cutting data and calculation of machining times

4. Calculation of machining costs per piece

5. Projection of tooling costs per piece

6. Calculation of performance (cutting forces, spindle power, torque moment)

7. Support during final acceptance and commissioning runs.

Additionally, we will provide you with the expert support you need when implementing your specific concept on site – anywhere in the world! Any question, Please contact us.

Delivery ways/Packing

La société dispose d'une ligne de production complète d'équipements de processus de fabrication de lames allant de la préparation des matières premières en poudre à la fabrication de moules, en passant par le pressage, le frittage sous pression, le meulage, le revêtement et le post-traitement du revêtement. Il se concentre sur la recherche et l'innovation du matériau de base, de la structure des rainures, du formage de précision et du revêtement de surface des plaquettes NC en carbure, et améliore constamment l'efficacité de l'usinage, la durée de vie et d'autres propriétés de coupe des plaquettes NC en carbure. Après plus de dix ans de recherche scientifique et d'innovation, l'entreprise maîtrise un certain nombre de technologies de base indépendantes, dispose de capacités indépendantes de R&D et de conception et peut fournir une production personnalisée pour chaque client.