- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

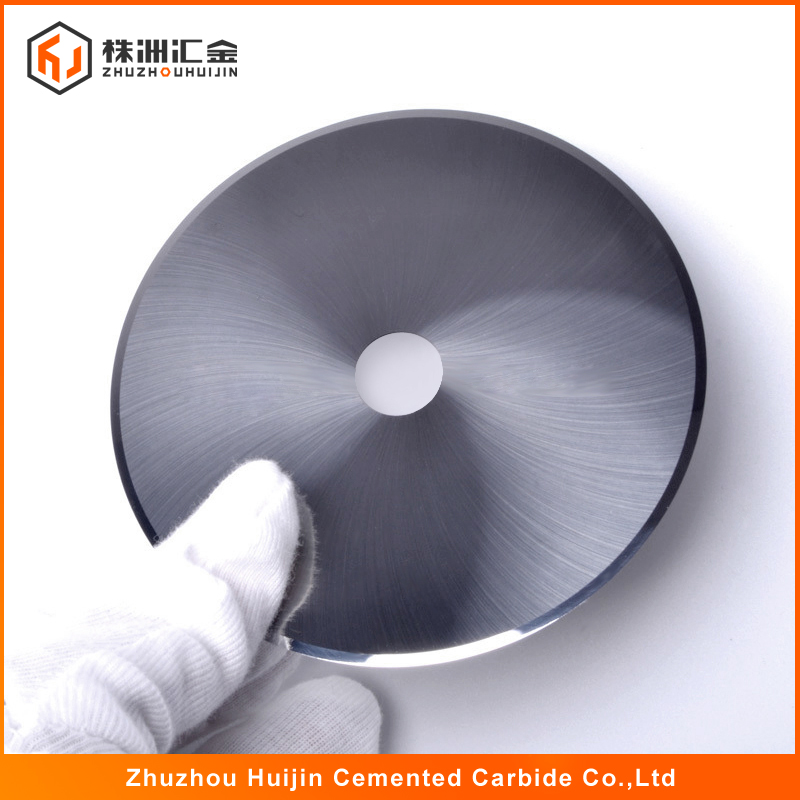

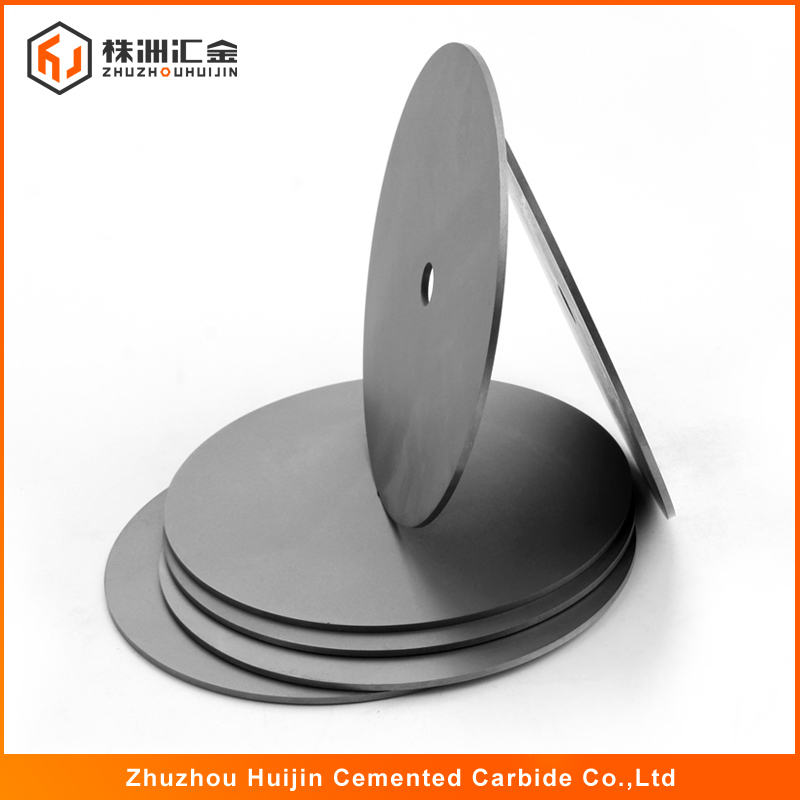

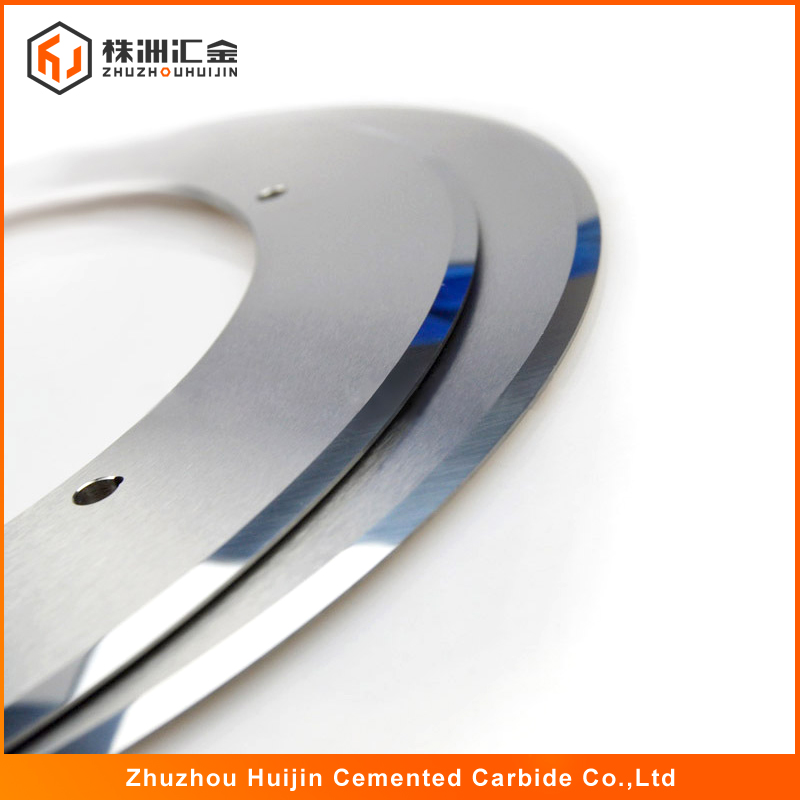

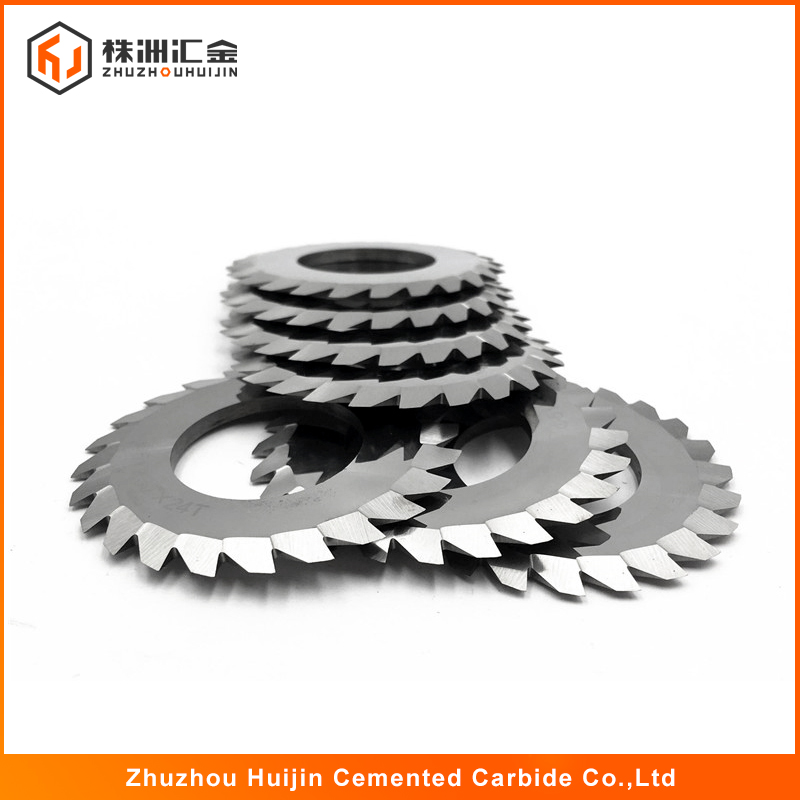

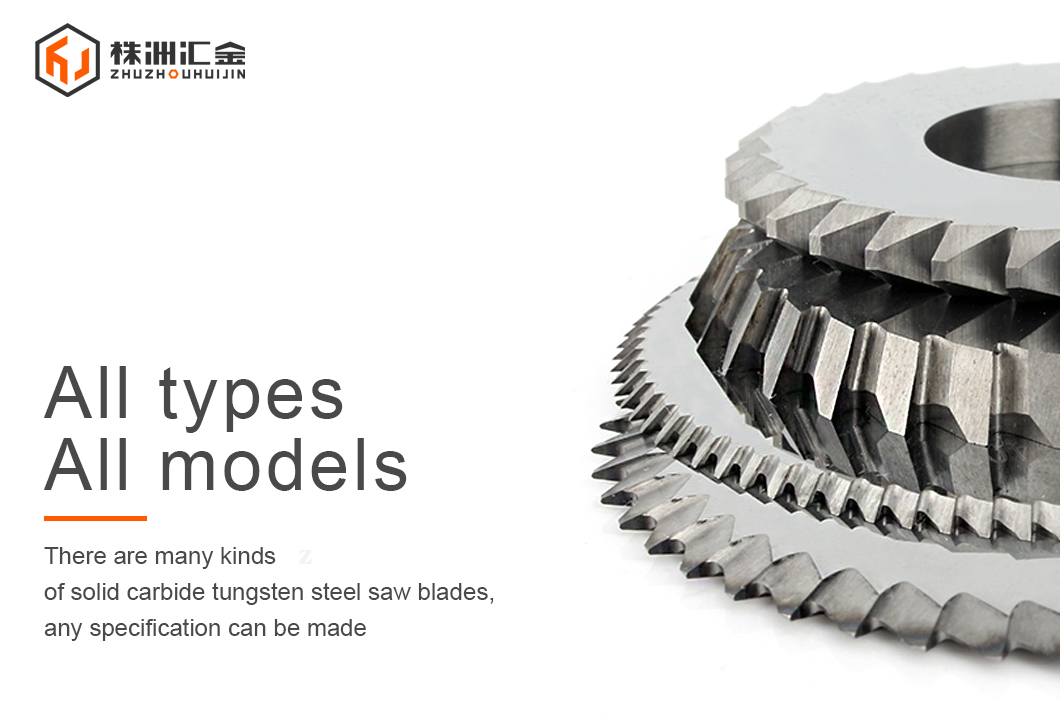

Custom carbide round cutter

Custom carbide round cutter

Widely used in: glasses, watches, machinery, electronics, motors, leather and other industries

Working type: Cutting / slotting

Surface: grinding and polishing to mirror

Service : OEM and ODM

Customized NON-Standard inserts OEM service:

1. We provide unmatched experience and customer service with complete confidentiality. We have a proven track record of over 15+ years in the carbide inserts manufacturing industry.

2. Our OEM services pair your blueprints and designs with manufacturing capabilities to make your product a reality.

3. Any products - any design - any compliance - any industry,small - medium - high quantities are welcome.

4.If you have specialize request, you can provide specifications of what you need in detail, files in CAD or sample please sent to sales@zzhardmetals.com.

OEM Process:

1. Free design.

2. Free samples test.

3. Determination of cutting data and calculation of machining times.

4. Calculation of machining costs per piece.

5. Projection of tooling costs per piece.

6. Calculation of performance (cutting forces, spindle power, torque moment).

7. Support during final acceptance and commissioning runs.

What you can expect from us:

1.Quick quotation .

2.Easy ordering .

3.Performance guarantee for given product and cutting data .

4.Competitive delivery times .

5.All major product groups within metalworking, e.g. turning, milling, and hole making, are available for customization, giving you the freedom to specify your own dimensions without having to pay the price of a special tool.

La société dispose d'une ligne de production complète d'équipements de processus de fabrication de lames allant de la préparation des matières premières en poudre à la fabrication de moules, en passant par le pressage, le frittage sous pression, le meulage, le revêtement et le post-traitement du revêtement. Il se concentre sur la recherche et l'innovation du matériau de base, de la structure des rainures, du formage de précision et du revêtement de surface des plaquettes NC en carbure, et améliore constamment l'efficacité de l'usinage, la durée de vie et d'autres propriétés de coupe des plaquettes NC en carbure. Après plus de dix ans de recherche scientifique et d'innovation, l'entreprise maîtrise un certain nombre de technologies de base indépendantes, dispose de capacités indépendantes de R&D et de conception et peut fournir une production personnalisée pour chaque client.