- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

5pcs 10pcs 20pcs set Carbide Rotary Burr

5pcs / 10pcs /20pcs set Carbide Rotary Burr

5pcs / 10pcs /20pcs set Carbide Rotary Burr

single cut & double-cut

Material:Cemented carbide

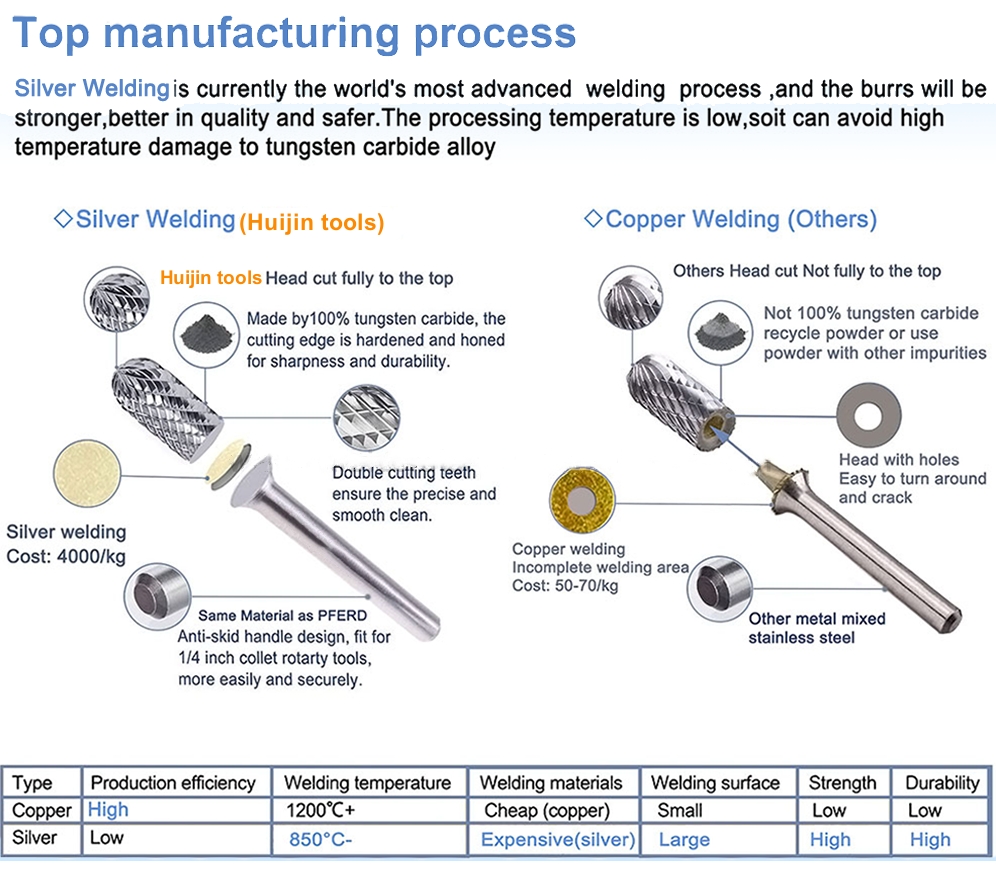

welding: silver welding

The carbide alloy rotary file is the fitter and mold labor's indispensable advanced tool, its characteristic is

substitutes for the belt handle small grinding wheel and the non-dust pollution, the service life is equal to

several hundred belt handle small grinding wheel, the processing effciency enhances above 5 times, below abrasive

machning degree of hardness HRC70 each metal and the nonmetallic meterial, grinding surface roughness

may reach Ral.6, convenience grasps, use to be simple, safe reliable, reduces the arduous manual labor greatly,

reduce the cost of production.

Material: 100% of raw materials.

Tolerance: strict tolerance extent control, which can reach +/-0.01mm;

Grades: various for choice: YG6, YG8, YG8C, YG11C,YG15C and so on.

Types: standard, conical, parabolic,ballistic

Physical performance: high hardness and impact toughness, very good mechanical & chemical stability.

Cemented carbide rotary file is widely used in machinery, automobile, ship, chemical industry, craft carving and other

industrial sectors, with remarkable effect. Its main uses are:

-- Fine machining various metal mold cavities.-- All kinds of metal, non-metal carving, and carving of craft gifts.

--Clean the flash, burr and weld of castings, forgings and weldments

--Chamfering, rounding and groove processing of various mechanical parts, cleaning of pipes, and finishing of

inner hole surfaces of mechanical parts

-- Polishing of impeller runner.

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Delivery ways/Packing

-Express companies: DHL, FedEx, TNT, UPS, etc.

-Airlines.

-Ocean shipping

A. Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product)

La société dispose d'une ligne de production complète d'équipements de processus de fabrication de lames allant de la préparation des matières premières en poudre à la fabrication de moules, en passant par le pressage, le frittage sous pression, le meulage, le revêtement et le post-traitement du revêtement. Il se concentre sur la recherche et l'innovation du matériau de base, de la structure des rainures, du formage de précision et du revêtement de surface des plaquettes NC en carbure, et améliore constamment l'efficacité de l'usinage, la durée de vie et d'autres propriétés de coupe des plaquettes NC en carbure. Après plus de dix ans de recherche scientifique et d'innovation, l'entreprise maîtrise un certain nombre de technologies de base indépendantes, dispose de capacités indépendantes de R&D et de conception et peut fournir une production personnalisée pour chaque client.