- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

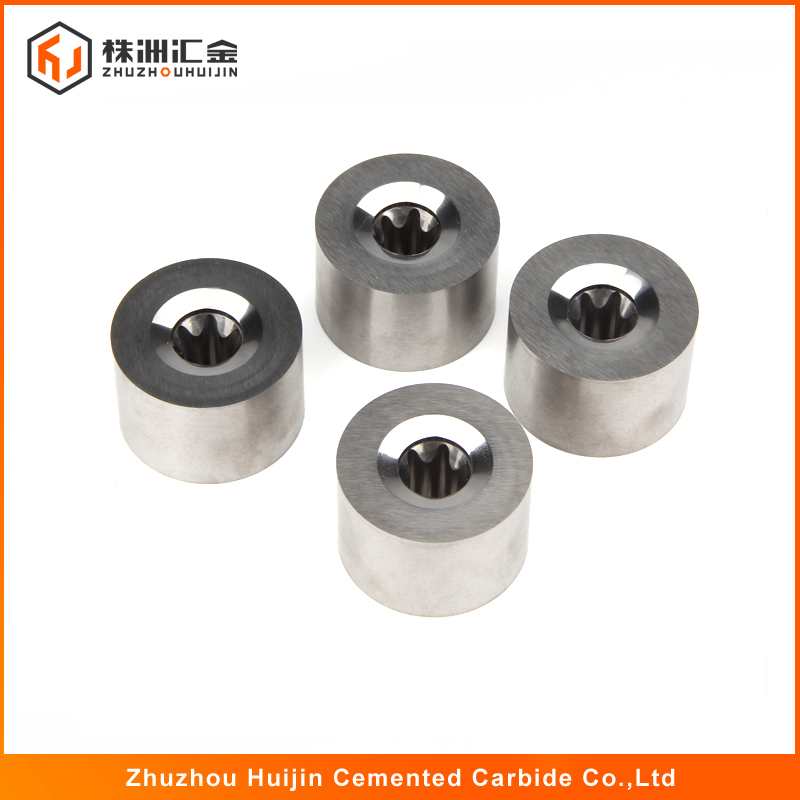

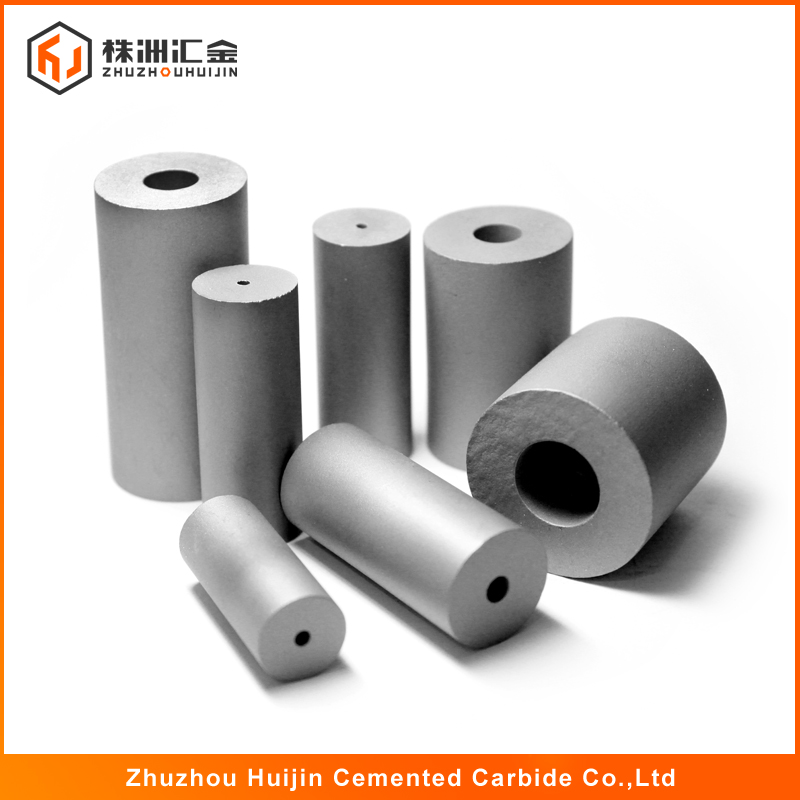

Tungsten carbide cold heading stamping dies

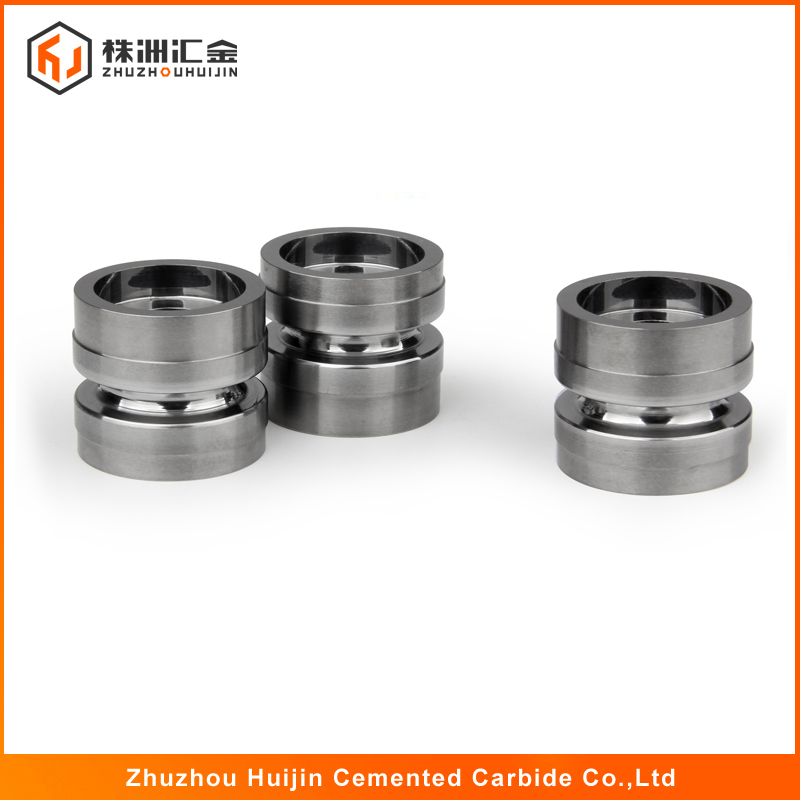

Tungsten Carbide Fine polishing Plum hole punching die

carbide cold heading dies/carbide punch dies

customized non standard die

tungsten carbide cold forging dies

Plum die carbide requires higher wear resistance and toughness. This mold is an irregular mold that needs

to be processed with slow wire cutting.

There are standard clubs size, specifications: T10, T15, T20, T25, T30, T35, T40, T45, T50 are commonly used specifications

We are a skilled manufacturer in China producing the most commendable carbide punch dies,

carbide heading dies, carbide forming dies, etc. Our tungsten carbide die has high precision, durability,

short delivery time, and affordable price.

100% raw material to produce tungsten carbide products.

Hip sintered, high hardness, high wear resistance

Various sizes and full types available

Reasonable price,Fast delivery time

OEM Customized(small order accepted,professional technical support)

ISO 9001 Certification

More details of specific type, please inform us Product information

Remark:Customed Size Will be welcome

product show

| Material grades ,Performance & application recommended | ||||||

| Grades | Wc% | Co% | Density | T.R.S | Hardness | Performance & application recommended |

| g/cm3 | MPa | HRA | ||||

| YG11 | 89% | 11% | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 85% | 15% | 14 | 2800 | 87.5 | For fabricating drawing dies of steel tubes and rods under high compressibility ratio;punching,stamping,forging tools under large stress. |

| YG20 | 80% | 20% | 13.5 | 3200 | 85.5 | For fabricating of staming dies for watch parts,spring plates of musical instruments,battery jays,small sized steel balls,screws,screw caps. |

| YG16C | 84% | 16% | 13.9 | 2900 | 85.5 | Impact resistance forging dies. |

| YG18C | 82% | 18% | 13.7 | 3100 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 80% | 20% | 13.5 | 3300 | 83 | Dies for wear resistant or impact resistant application. |

| YG22C | 78% | 22% | 13.3 | 3500 | 82.5 | Nut forming dies and high impact resistance forging dies. |

| YG25C | 75% | 25% | 13.1 | 3600 | 82 | Stainless bolt header dies and rollers. |

| HJ80.1 | 75% | 25% | 13.05 | 3800 | 83.2 | It is suitable for screw cap forming dies with high strength (highest impact-resistant forging dies). |

Necessary information required for accurate quotation :

Specification ( like OD*ID*Length size,shape,angle etc.)

Surface condition: sintered blank or fine grinding

Tolerance on dimension ( if you have)

If you have detail drawing contain all above information ,you can send drawing to us Tungsten carbide grade, or chemical composition.

If you are not quite clear about which tungsten carbide grade is suitable, please provide us the applications,we will suggest suitable grade base on your

Ang kompanya adunay usa ka kompleto nga sulud sa proseso sa paggama sa mga kagamitan sa linya sa produksiyon gikan sa pag-andam sa hilaw nga materyales sa pulbos, paghimo sa agup-op, pagpindot, pag-sinter sa presyur, paggaling, pag-coat ug pag-coat post-treatment. Gipunting niini ang panukiduki ug pagbag-o sa base nga materyal, istruktura sa groove, pagporma sa katukma ug pagtabon sa nawong sa mga pagsal-ot sa carbide NC, ug kanunay nga gipauswag ang kahusayan sa machining, kinabuhi sa serbisyo ug uban pang mga kabtangan sa pagputol sa mga pagsal-ot sa carbide NC. Human sa kapin sa napulo ka tuig nga siyentipikong panukiduki ug kabag-ohan, ang kompanya nakahanas sa daghang mga independente nga core nga teknolohiya, adunay independente nga R&D ug mga kapabilidad sa pagdesinyo, ug makahatag og customized nga produksiyon alang sa matag kustomer.